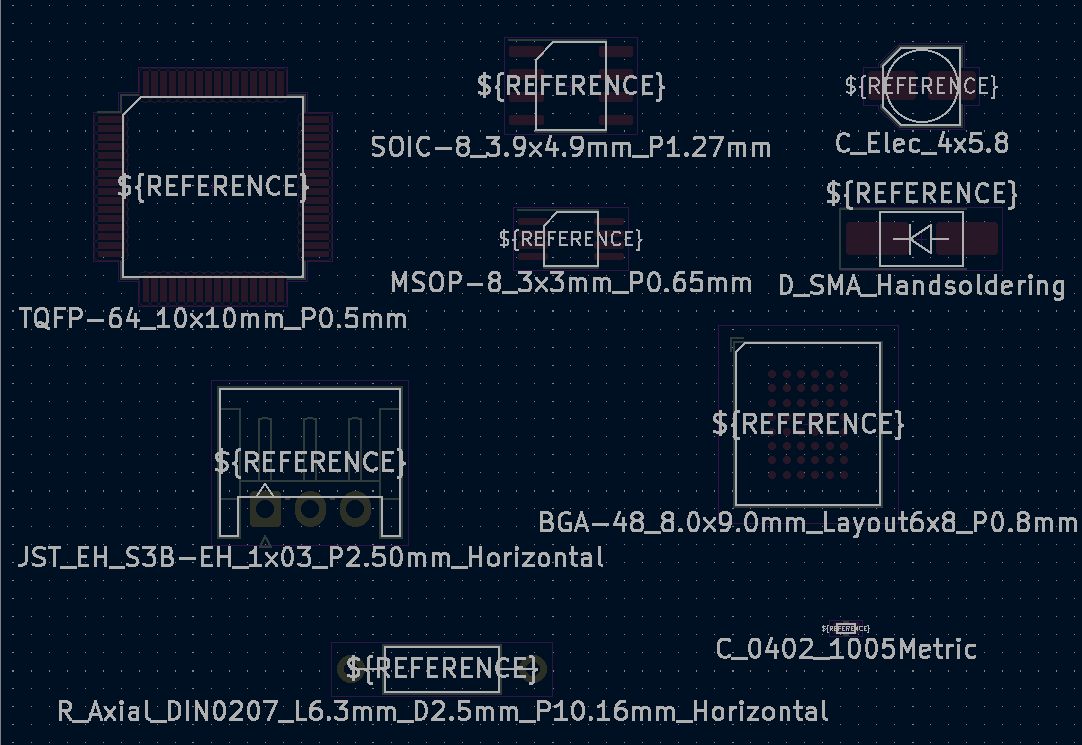

F5.2 Fabrication layer requirements

The fabrication layers are used to display the simplified mechanical outline of components on the PCB.

KiCad refers to the fabrication layers as:

-

F.Fab- Front fabrication layer -

B.Fab- Back fabrication layer

The following elements must be provided on the fabrication layer(s)

-

Simplified component outline must be provided on

F.Fablayer-

Outline uses line width between {

0.10mmand0.15mm} (recommended0.10mm) -

Outline should be simplified and not display complex features

-

For outlines based on the component body shape, the nominal size is used

-

-

Footprint polarisation / location of pin-1 is drawn

-

For IC packages, bevel is drawn at corner next to pin-1

-

Bevel should be

1mmor25% of package size(whichever is smaller) -

For connectors, a small arrow indicator drawn next to pin-1 should be used

-

-

Component value (footprint name) must be displayed on the

F.Fablayer-

Recommended text size =

1.0mm -

Allowable text size = {

0.5mmto1.0mm} -

Text thickness should be approximately

15%of text size ( with allowances for variation for aesthetic reasons) -

Placed below (positive y direction) the part outline.

-

-

A second copy of the reference designator (RefDes) must be provided on the

F.Fablayer. To add a second RefDes item, add a text object with the value${REFERENCE}-

RefDes must be centered on component body (inside component outline)

-

Orientation of RefDes should match major component axis

-

Size of text should be scaled to match component size

-

It is recommended to scale it such that 4 characters fit without overlapping other features of the same layer.

-

If it is not possible to fit at least 3 characters with the text size restrictions, then the reference should be moved outside (but scaled to smallest allowable text size)

-

-

Recommended text size =

1.00mm -

Allowable text size = {

0.5mmto1.0mm} -

Text thickness should be approximately

15%of text size (with allowances for variation for aesthetic reasons)

-