*.kicad_mod textThe KiCad Library Convention (KLC) is a set of requirements for contributing to the official KiCad libraries. Users wishing to submit or update library files should be familiar with these guidelines.

The KLC are a set of guidelines, rather than rules. Electronic component libraries are diverse and complex, and exceptions can be made at the discretion of the library team.

Where the KLC deviates from a particular datasheet or manufacturer recommendation, the datasheet should take preference unless there is a good reason not to do so (which should be clarified by a librarian).

Where the KLC is unclear, users should attempt to match the convention of existing library components, or seek further clarification.

Refer to the contribution guidelines for introductory information on contributing to the KiCad libraries.

KLC Helper Scripts

The KiCad library team has developed a set of Python scripts which can be used to help test if library components conform to the KLC requirements.

When a merge request is made to the libraries, the contributed files are automatically checked using these scripts. It can be helpful to run these scripts on your local machine before submitting a PR, as it will help speed up the process of merging your contribution(s) into the library.

To run the footprint checker script, for instance, cd into the "kicad-library-utils/klc-check" directory, then run the Python script ./check_footprint.py path_to_fp1.kicad_mod path_to_fp2.kicad_mod -vv. This will carefully check your footprint according to the KLC requirements laid out below, notifying you of any discrepancies, errors, or violations. See more usage examples in the readme at the link above.

Note: While many of the KLC guidelines are checked by these scripts, there are some which are not covered. Additionally, any PR requires manual checking by a member of the library team.

GitLab Wiki

The KLC provides a comprehensive foundation for anyone contributing to the official KiCad libraries. However, the KiCad Libraries GitLab Wiki serves as an invaluable addition to the KLC website.

The GitLab Wiki offers resources that go beyond the formal guidelines, including:

-

Practical guidance: Detailed explanations on applying KLC guidelines in typical projects, along with specific examples and best practices

-

Community contributions: Frequently updated tips and information contributed by the community, helping users avoid common mistakes and troubleshoot issues

-

Exceptions and clarifications: Guidance on specific cases where deviations from the guidelines are sensible or necessary

Anyone reviewing the KLC website should also explore the GitLab Wiki to gain deeper insights into guideline application and access useful tools and extended information for a smoother contribution process.

Refer to the KiCad Libraries GitLab Wiki for more details.

General Library Guidelines

The general library guidelines apply to all library elements (symbols / footprints / models / templates / 3D models). However, these guidelines may be overridden in some cases by specific exceptions described in further sections.

G1 - General Guidelines

G1.1 Only standard characters are used for naming libraries and components

Filenames, symbol names, footprint names, model names, 3D model names, and template names must contain only valid characters, as determined below:

-

Alphanumeric characters (

A-Z,a-z,0-9) -

Underscore

_ -

Hyphen / dash

- -

Period / dot

. -

Comma

, -

Plus symbol

+

This character set ensures that symbols will be compatible with all filesystems, and will not cause any issues due to character rendering.

Further, filenames and symbol names must not use the space character. This can cause issues with string escaping and is best avoided.

G1.2 Withdrawn

This rule was withdrawn.

G1.3 Libraries are organized by functionality

Rather than grouping components (e.g. symbols, footprints) by their manufacturer, KiCad libraries are organized by component functionality. This grouping strategy has a number of key benefits:

-

Similar components are grouped together, allowing alternative parts to be easily substituted

-

If possible, symbols should be derived from existing symbols to reduce library size

-

Generic parts which are produced by multiple manufacturers are supported

Library organization should follow the general form as described below, with each element separated by the underscore (_) character:

-

Library function

-

Library sub-function

-

Tertiary qualifier

-

Manufacturer name

-

Component series name

-

Extra library descriptors

Note: Some of the elements listed above may be omitted if not required.

For specific examples, refer to the guidelines for organizing symbol libraries and footprint libraries.

G1.4 English language should be used throughout libraries

KiCad software is used by people who speak many different languages. The KiCad software provides translations for these languages, but the library files do not provide translations.

Library files should be written using English, excepting where specific component names are non-English (for non-English manufacturers).

Where potential differences in spelling and grammar exist, American English should be given preference.

-

Colorinstead ofColour

G1.5 Plural naming is to be avoided

In general, plural naming (e.g. for libraries) should be avoided, as pluralisation of some words is inconsistent. Non pluralized names should be used in preference:

-

Sensor_Temperatureinstead ofSensors_Temperature -

Memory_Flashinstead ofMemories_Flash -

TerminalBlockinstead ofTerminalBlocks

G1.6 Capitalization conventions

-

Acronyms should be capitalized

-

MCU(microcontroller) -

FPGA(field programmable gate array)

-

-

Manufacturer names should be capitalized according to the manufacturer

-

Microchip -

ROHM -

Texas -

NEC

-

-

Unless separated by delimiters such as

_,-,., words should be separated using CamelCase convention, with the first letter of each word capitalised-

TestPoint -

BatteryHolder

-

G1.7 Library files use Unix style line endings

Library files must always be commited to GitLab using Unix-style line endings. This means that lines are terminated using the LF (line feed) character, rather than the DOS style CR+LF line endings.

KiCad library files must be compatible across multiple operating systems, and users should be able to contribute without generating unnecessary noise in the files by constantly changing line endings.

When using the KiCad libraries on a Windows PC, the line endings in the library files may be automatically converted to CR+LF. This is fine, as long as any contributions made to the libraries observe the LF line ending requirements.

This issue is addressed by insisting that all KiCad libraries include a .gitattributes file. This file ensures that the line endings are automatically converted by Git.

An example of a simple .gitattributes file which ensures footprint files have correct line endings is as follows:

Note: The KiCad library repositories should already have the correct .gitattributes file in place to achieve this

G1.8 Contributions to the official library must be made using the current stable version

Contributions of library assets must be created in the latest stable version of KiCad.

This is to avoid problems caused by changes in how assets are stored in different versions of KiCad. (Changes in how line ordering is determined, how strings are escaped, etc.) Another reason is to avoid including features not supported by the latest stable release.

G1.9 Dimensional units

-

When specifying a dimension (e.g. in a footprint name) the units must always be provided:

-

3mm- millimeters -

1in- inches

-

-

When specifying areas or volumes, the coordinate order is

X-Y[-Z], which is equivalent towidth-height[-thickness]. -

When specifying multidimensional units (e.g.

widthxheightxthickness) then the units only need to be appended once-

3x4x7mm- 3mm x 4mm x 7mm

-

-

Metric units are preferred, where appropriate

-

Linear dimensions should be specified in millimeters

-

Angular dimensions should be specified in degrees

-

Temperature should be specified in degrees Celsius

G1.10 Embedding files

Symbols and Footprints must not contain embedded files. Thus the embedded fonts checkbox also should never be set.

The feature is intended to embed datasheets, 3D models or fonts. All of those most likely are not compatible with the library license. Also, this would vastly increase the file size of the repositories.

Possible exceptions from this rule:

-

SPICE models in symbols

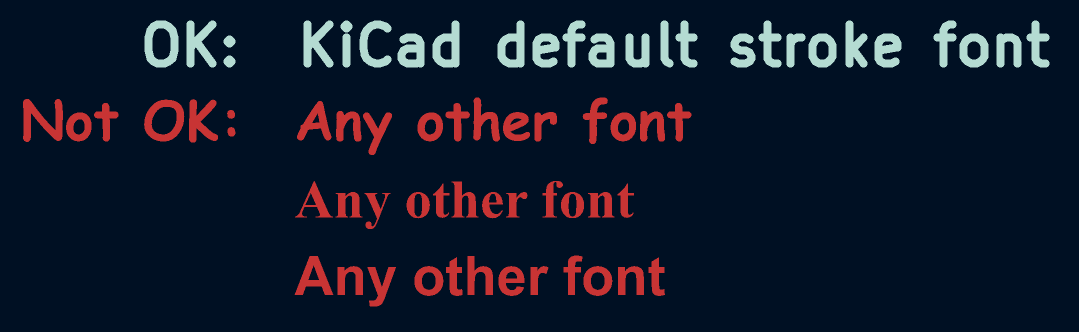

G1.11 Default font

All text should use the default KiCad stroke font.

Exceptions:

-

Text in 3D models may use "real" fonts as appropriate. Open source fonts should be used to allow others to edit the models.

-

Text in graphical symbols may use graphical polygons as text when they require a specific font as part of a logo, but may not embed their own fonts (see G1.10).

G2 - Generic and Fully Specified Symbols

G2.1 Definition of terms: Generic and fully specified symbols

KiCad has two workflows regarding what a symbol represents and when it is assigned a footprint. It can be done in the library in which case the symbol represents an exact part or using the "Assign Footprints" tool at the end of the design process.

Generic symbols

Generic symbols can be used with multiple footprints. They do not have a default footprint assigned. Generic symbols allow flexibility in the design workflow. For this workflow the symbol placed into the schematic is typically selected to fit the intended function instead of fitting a particular part. The footprint assignment happens later when the exact part number is selected. Using generic symbols allows a small number of library symbol elements to represent a very large number of possible component combinations.

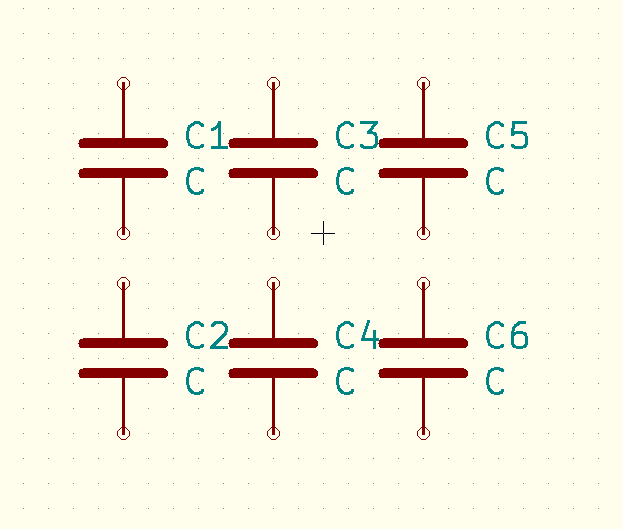

An example of the use of generic symbols are the Resistor and Capacitor symbols available in the KiCad library. These symbols do not have an assigned default footprint, as there are many possible compatible footprints.

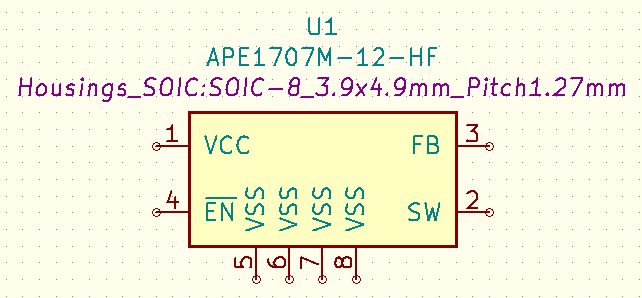

Fully specified symbols

Fully specified symbols define a matching footprint, and are named based on the MPN (manufacturer part number). Such symbols do not depend on the user to select the correct footprint later but can have alternative footprints defined using footprint filters such that the user can select an alternate footprint.

A fully specified symbol together with a footprint specialized to one component are called an atomic part. A library of only such parts is called an atomic library. Confusingly, some users refer to a fully specified symbol as an atomic symbol.

Where to use which type

The official library requires fully specified symbols except for a small number of libraries that contain only generic symbols. These generic libraries are:

-

Device -

All

Connectorlibraries -

The logic family libraries like

74xx,4xxx, …

G3 - Special Pin Numbering

G3.1 Relays

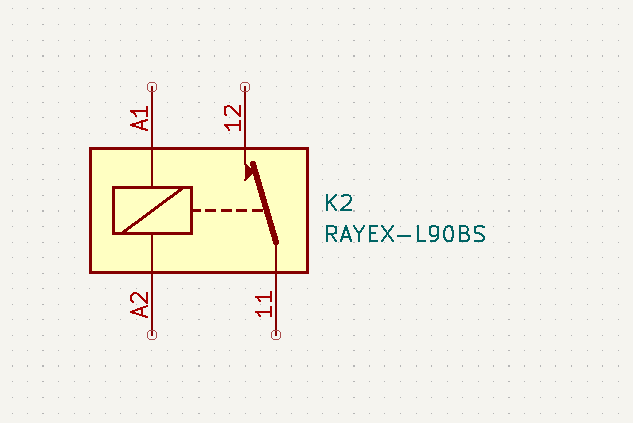

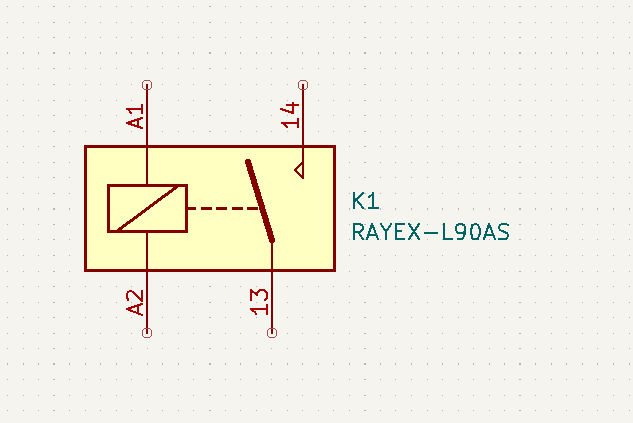

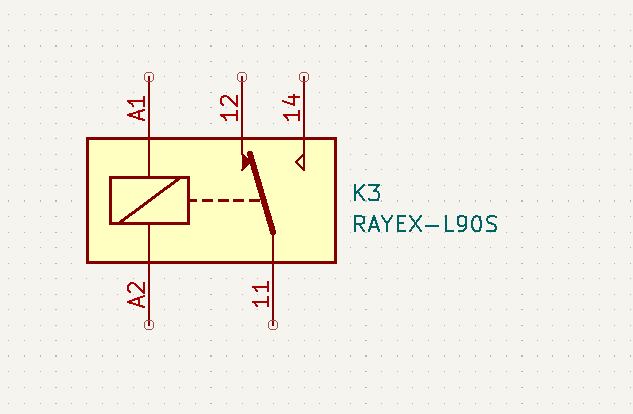

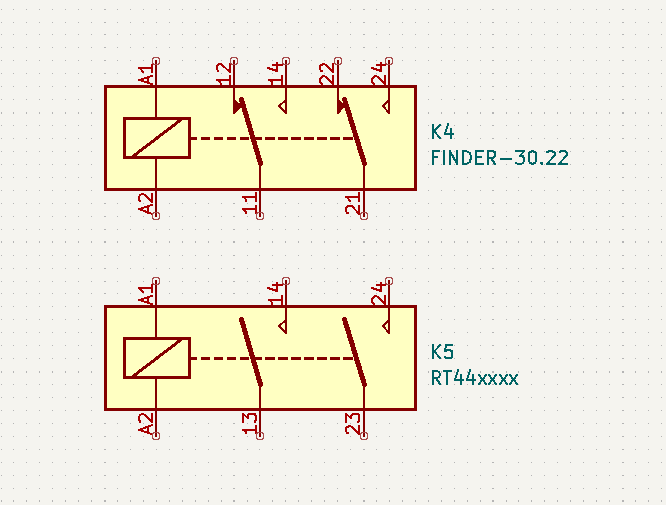

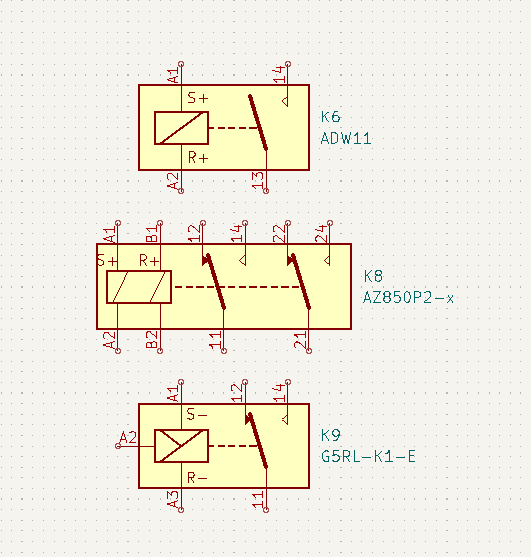

Pin numbers for relays follow EN 50005.

-

The coil contacts shall be named

A1andA2.-

For more complex relay magnetics, each coil pin shall have a letter and a number. The letter shall describe which coil the pin belongs to; the digit shall describe the tap number in that coil.

-

Bistable relays shall have current flowing at the A1 pin in the A coil

Setthe relay and be labelledS+orS-. -

Bistable relays should be labeled

R+orR-in theResetcoil or direction as well. -

In Bistable relays, labeling the positive direction that the current flows from shall be preferred over labeling the negative direction that the current flows to. Where it is not possible to label the positive direction, such as center-tapped relays with current always flowing from the center tap, the negative direction should be labelled.

-

-

Contacts shall have two digits each. The first digit shall be the index number of the pole group; the second digit shall describe the function.

-

Normal-Close (NC) contacts shall be

x1andx2 -

Normal-Open (NO) contacts shall be

x3andx4 -

Changeover contacts shall be

x1for the common contact,x2for NC, andx4for NO

-

NC Contacts Example

NO Contacts Example

Changeover Contacts Example

Multiple Poles Example

Bistable Relay Example

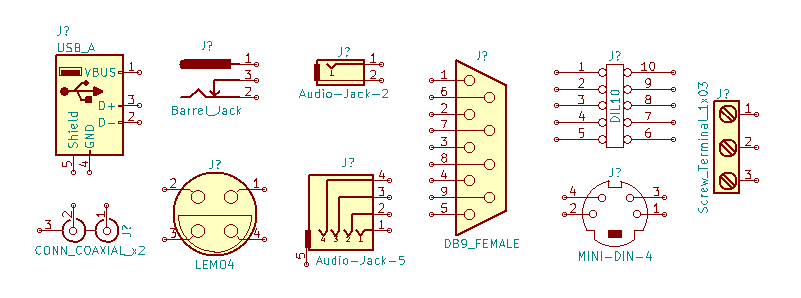

G3.2 Audio Connectors

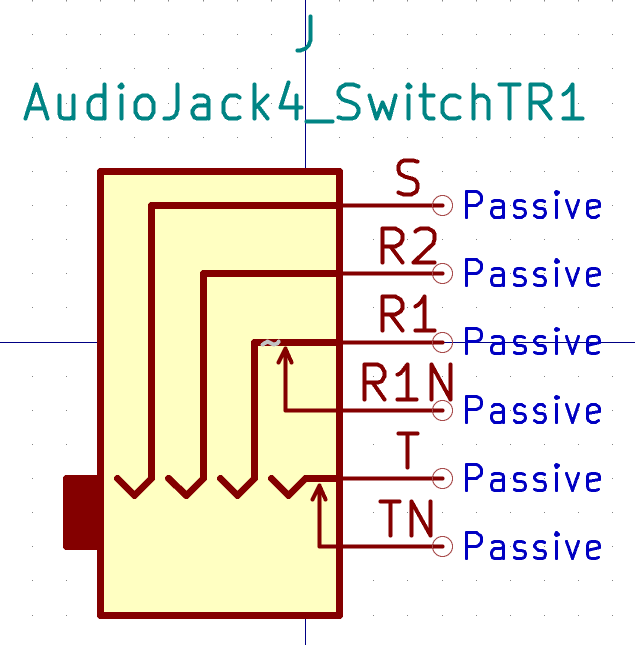

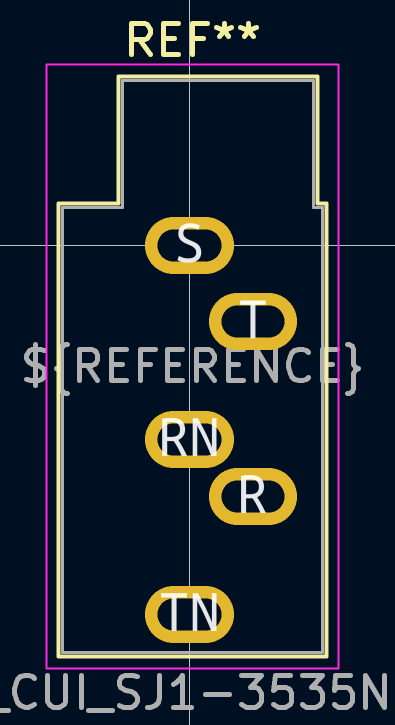

Audio jacks have specific pin names which are industry-standard and broadly understood. By giving the symbols and footprint the same generic pin names, a single generic symbol can be used for a variety of footprints without needing many manufacturer-specific symbols.

-

The basic pin names are "T" (tip), "R" (ring), and "S" (sleeve). "R" is used for stereo or balanced systems and is not always present.

-

Multiple ring connections may be used, and in that case they are named "R#" where "#" is a number starting at 1, with "R1" closest to "T". See AudioJack5 for a symbol with three ring terminals.

-

Some pins may be "normalled" (or switched) meaning signal flows through the connector when no jack is inserted, and the signal path is broken and re-directed from the jack when it is inserted. The normalled pins are given a suffix "N" after the name of the pin they switch. `AudioJack4_SwitchTR1' shows the "T" and "R" pins being switched.

Footprints covered by this rule should not have a polarity/pin1 marking. This overrides the F5.1 rule.

Note that XLR connectors have standard pin names of 1, 2, and 3. Combination jacks will when use both letters and numbers. An example of this symbol is XLR3_AudioJack3_Combo.

Examples

Symbol Guidelines

The following guidelines apply to schematic symbols and symbol library files.

S1 - Symbol Libraries

S1.1 Symbol libraries should be categorized by function

Symbol library names must be defined based on the priority list below, with each element separated by the underscore (_) character:

-

Function (e.g.

Sensor,Amplifier,MCU) -

Sub-function (e.g.

Temperature,CurrentSense) -

Tertiary qualifier (e.g.

CMOS) -

Manufacturer name (e.g.

Atmel,Infineon) -

Symbol series name (e.g.

PIC24,STM32) -

Extra library descriptors (e.g.

Deprecated)

Note: Some of the elements listed above may be omitted if not required.

Example symbol library names:

-

Power_Monitor- Power monitoring components -

Sensor_Temperature- Temperature sensors -

Driver_Motor- Motor drivers -

MCU_Microchip_PIC32- PIC32 microcontrollers from Microchip

S2 - Symbol Naming

S2.1 General symbol naming guidelines

-

Library naming should not be duplicated in symbol name

-

If symbol with same name exists for multiple manufacturers, the manufacturer name is written first

-

Fully specified symbols are named based on the manufacturer part number

-

If multiple manufacturers produce compatible parts but their part number suffixes for specifying the package differ, then the common base part number is used with clear name suffix for the footprint (e.g.

L78L05_TO92) -

Non-functional parts of the MPN must be replaced with a wildcard. (Refer to requirements for the use of wildcards in MPN)

-

-

Generic symbols use the device type

-

May be shortened for common components (e.g.

ConnforConnector) -

Reference designator may be substituted for common components (e.g.

D,C,LED)

-

-

Indicate quantity of elements for symbol arrays (e.g. resistor array with 8 elements -

Resistor_x8) -

Any modification of the original symbol, indicated by appending the reason

-

Different pin ordering -

Q_NPN_CBE,Q_NPN_BCE -

For multi-unit variants of typically single-unit symbols add the suffix

_Split

-

S2.2 Non-functional variations in part number should be replaced with wildcard

Manufacturer Part Numbers (MPN) often include variations that are non-functional in terms of schematic entry and PCB layout.

Examples of parameters considered non-functional:

-

Temperature rating of the component

-

Packaging information (e.g. reel, tray, tape)

-

RoHS / PbFree information

Examples of parameters considered functional are those that affect the schematic or layout of the part:

-

Electrical variations - these indicate important different characteristics (e.g. different supply voltages)

-

Package options - these indicate different footprints and/or pinouts

To capture every possible combination of part variation would require a large number of derived symbols and is to be avoided.

-

Where an MPN has options for such non-functional variations, these portions of the MPN should be replaced with the wildcard character (lowercase

x).-

If these non-functional parts of the MPN are at the end of the symbol name then the wildcard should be omitted.

-

-

Functional variations should be captured in the symbol name.

-

If there’s only one functional variation of the part, the wildcard does not need to be applied

-

Example:

TPS3430has only one variant:TPS3430WDRCR. So the name should beTPS3430WDRC, rather thanTPS3430xDRC.

-

S2.3 Where parts are available in multiple footprint options, a separate symbol must be drawn for each footprint

Many electronic components are provided in multiple packages. These may or may not be pin compatible.

Fully specified symbols require a separate symbol for every package. If they are pin compatible, the derive from existing symbol function must be used. Footprints in KiCad have a 1:1 relationship with their 3D model. This means multiple footprints are required where the 3D model has functional differences even if the footprints are identical (for example when 3D model height differs).

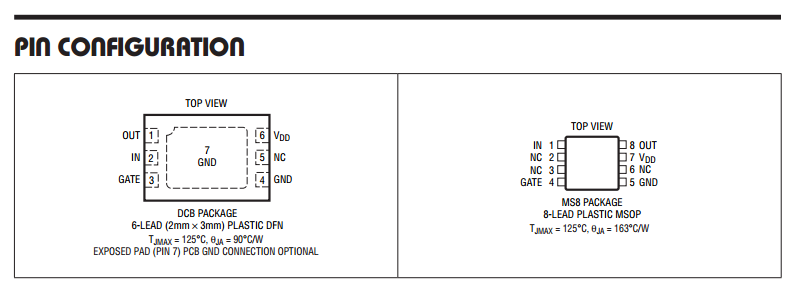

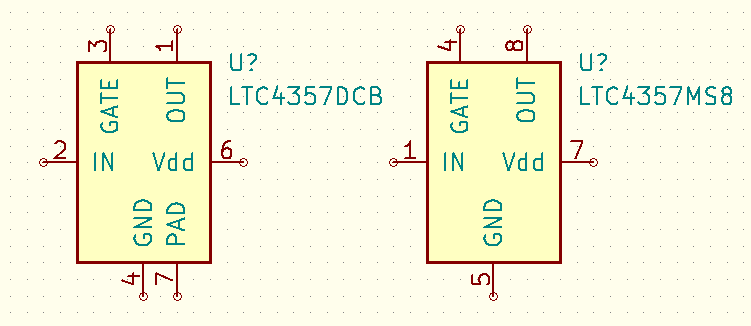

e.g. LTC4357

This part comes in two distinct packages each requiring a separate footprint. Hence a symbol for each variant must be drawn.

For naming of the symbols refer to General symbol naming guidelines

Where possible, the symbols should be drawn such that they can be swapped in the schematic with minimal disruption to wire connections.

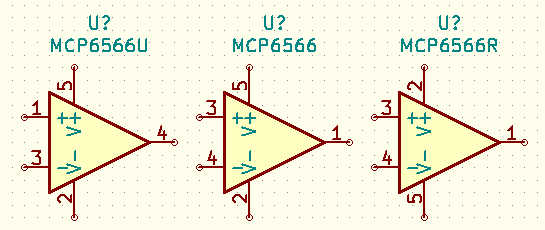

As a further example we shall consider the comparator MCP6566 which is available in three SOT-23-5 versions, each with a different pinout.

In this case, a separate symbol must again be drawn for each version, and named according to the convention called out in the datasheet.

S3 - General Symbol Requirements

S3.1 Origin is centered on the middle of the symbol

For symmetrical symbols, the symbol must be centered around the origin (0, 0) in the symbol editor.

Exception:

For non-symmetrical symbols, or symbols where this requirement would move pins off the 100mil grid, then the symbol should be placed as close to the origin as possible while observing the pin grid alignment requirements.

S3.2 Text fields should use a common text size of 50mils

-

All text fields (pin name, pin number, value, reference, footprint, datasheet) should use a text size of

50mil(1.27mm). -

Pin names and pin numbers can use a text size as small as 20mil if the symbol is small or has special geometry.

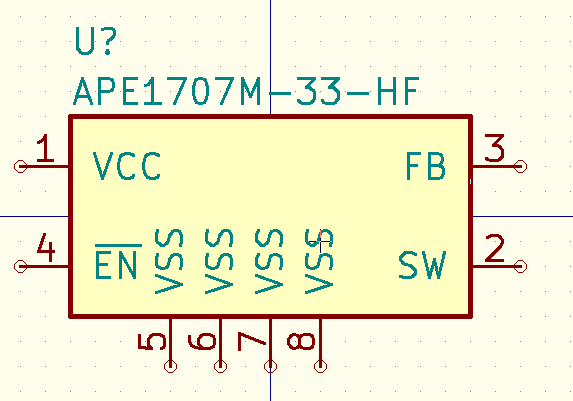

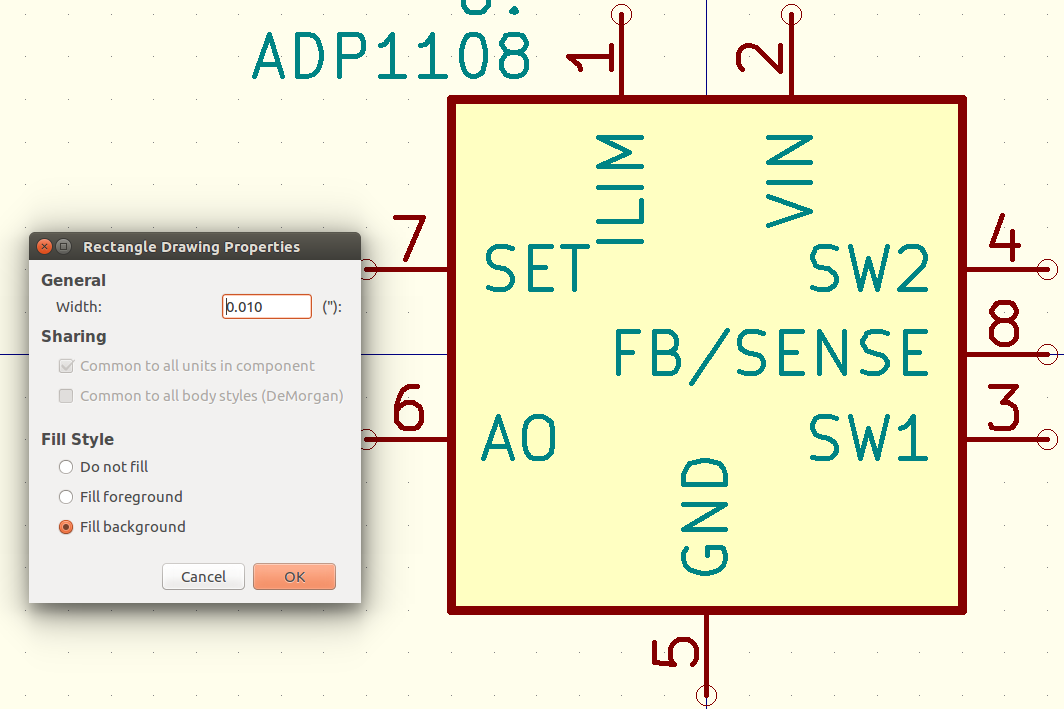

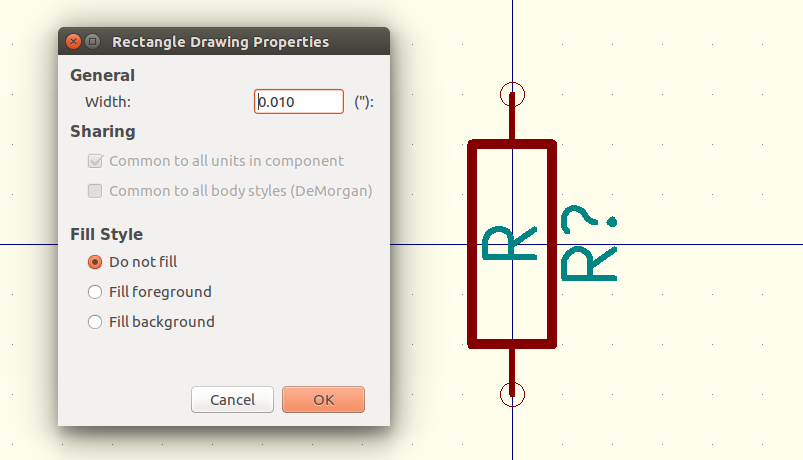

S3.3 Symbol outline and fill requirements

-

Symbol body must have a line width of

10mil(0.254mm) -

Black-box symbols (e.g. ICs with hidden functionality) should be filled with background color

-

Simple components (e.g. discrete components or those with a distinctive shape) should not be filled with background color

Fill background

Do not fill

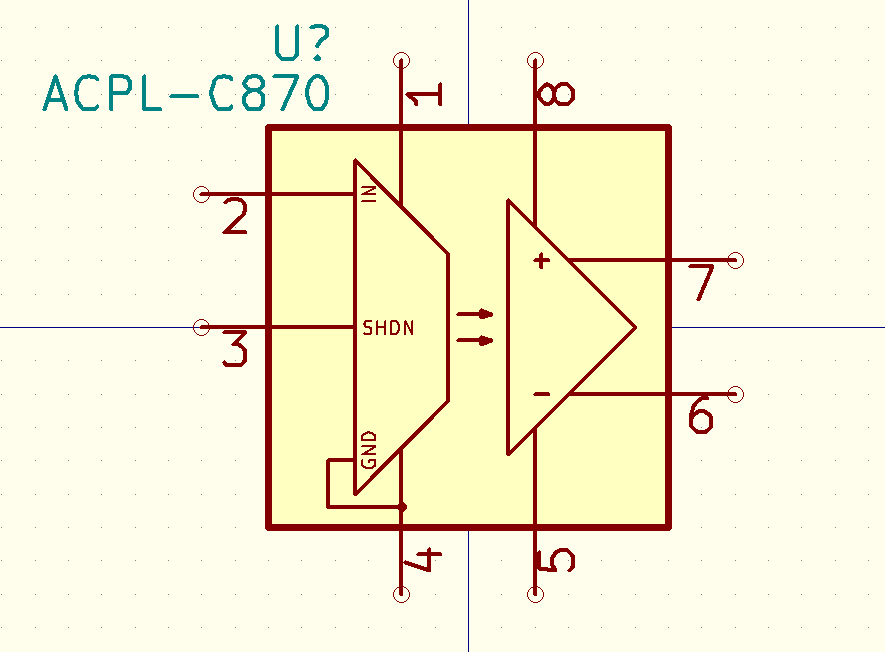

S3.4 Symbols with complex functionality may incorporate simple functional diagrams

For black box symbols with complex functionality (e.g. special function ICs), a simplified diagram of the symbol functionality may be drawn on the symbol. This may be used to provide functional clarity in a schematic.

-

Functional drawing must remain simple

-

Do not add functional drawings for multi-function components (e.g. microcontrollers)

S3.5 Pin connection points must be placed outside of the symbol

Connection points for symbol pins must be placed outside the symbol body and must not require a connecting wire to cross the symbol.

Example of incorrect symbol:

Example of correct symbols:

S3.6 Pin name position offset

-

Pin name position offset must not exceed

50mil(1.27mm) -

Pin name position offset should not be set less than

20mil(0.508mm) -

Preferred value is

20mil -

Larger offset allowed to accomodate particular symbol geometry

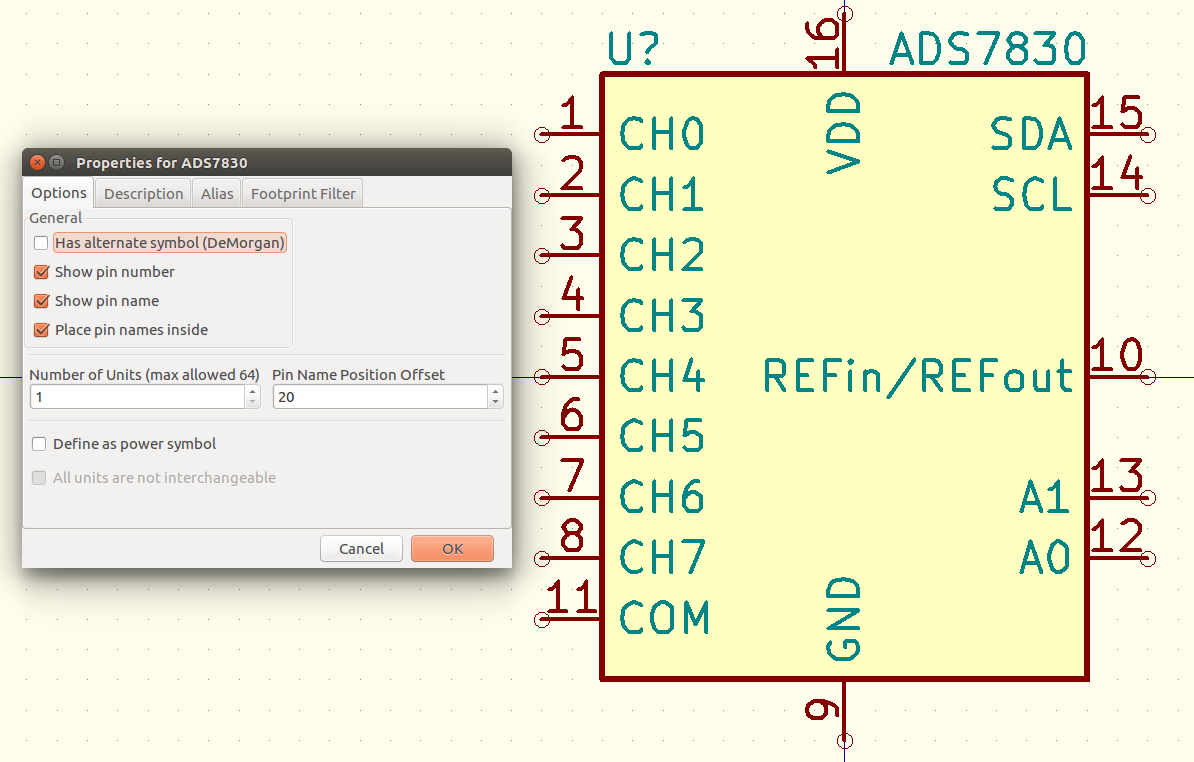

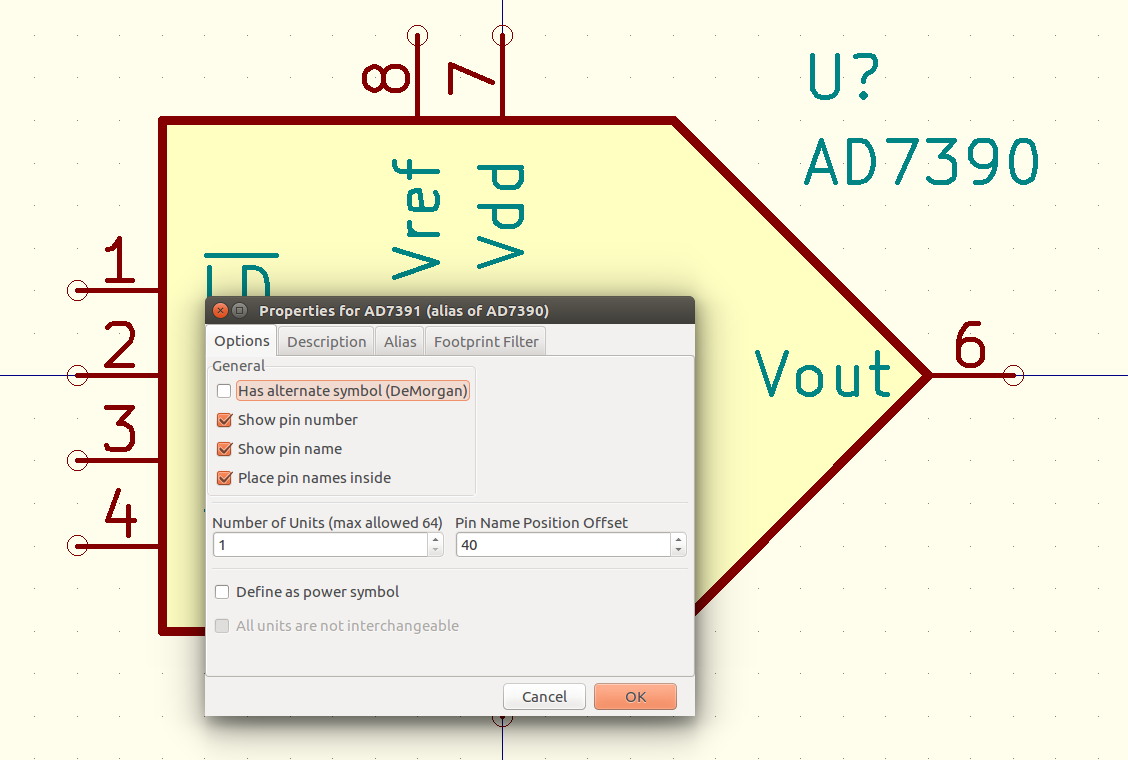

Examples:

S3.7 Pin numbering for specialized pads

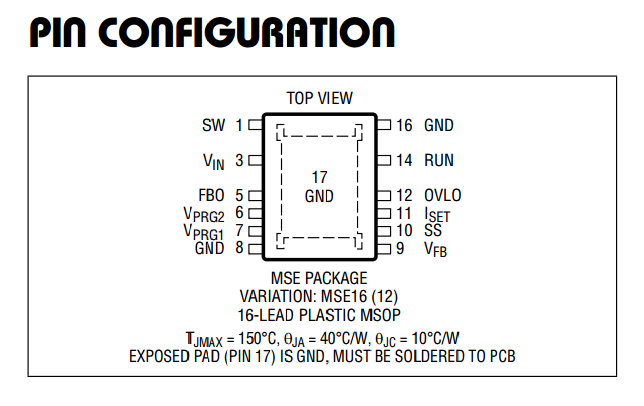

For IC components with exposed pads, the number of the exposed pad should start one greater than the pin-count of the footprint.

For a SOIC-8 package with a single exposed pad, the exposed pad will be assigned the number 9

Shielded components use "SH" as the pin number for connecting the shield. For a pin to qualify as the shield pin it must be connected to a metal enclosure. For connectors it must connect to the shield of the cable.

Parts that include mechanical mounting pads without electrical use, get the pin number "MP". Non plated through holes do not get any pad number assigned. (They do not get a pin in the symbol.) An example for such a pure mechanical mounting pad would be the pads for the two metal leads on the side of Molex picoblade smd connectors.

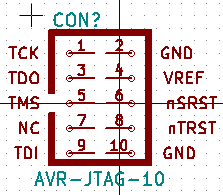

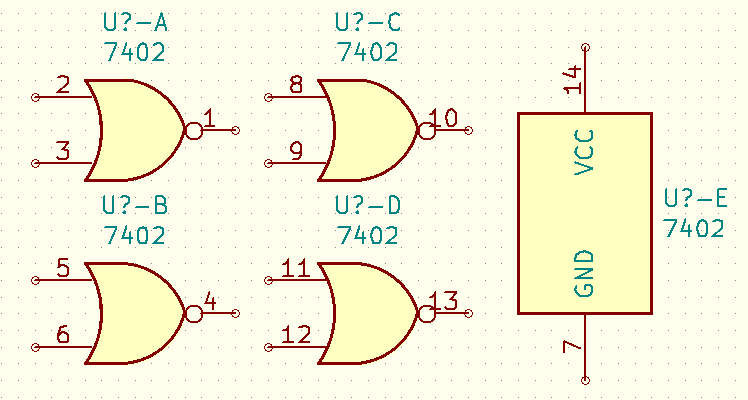

S3.8 Multi unit symbols

-

For symbols with multiple units that are drawn separately, where the units share common power pins, a separate unit should be drawn which contains these power pins.

This approach should not be taken for single-unit symbols. Power pins in this case must be drawn on the same symbol as the logic pins.

S3.9 De-Morgan representation

A symbol should not have an alternate body style. The De Morgan representation feature should not be used.

S4 - Pin Requirements

S4.1 General pin requirements

-

Using a

100mil(2.54mm) grid, pin origin must lie on a grid node (IEC-60617) -

Pins should have a length of at least

100mil(2.54mm)-

Pin length can be increased in steps of

50mil(1.27mm) -

The number of characters in the pin number determine a pin’s length. When there are two characters in the pin number then

100mil(2.54mm) long pins should be used, when three characters then150mil(3.81mm) long pins should be used, etc. -

Pin length must not exceed

300mil(7.62mm) -

Shorter pins are allowed on simple symbols for discrete devices such as resistors, capacitors, etc.

-

All pins on a symbol must have the same length

-

-

Pin numbers must be unique (no two pins may have the same number)

-

Pin names should match the pin names as specified in datasheet

S4.2 Pins should be grouped by function

Where possible, pins should be grouped by similar function, rather than by their physical location on the associated footprint. This provides cleaner schematic routing and symbols are easier to understand in the schematic.

-

Pins with similar functions should be grouped together:

-

SPI_MISO,SPI_MOSI,SPI_CS,SPI_CLK -

UART_TX,UART_RX

-

-

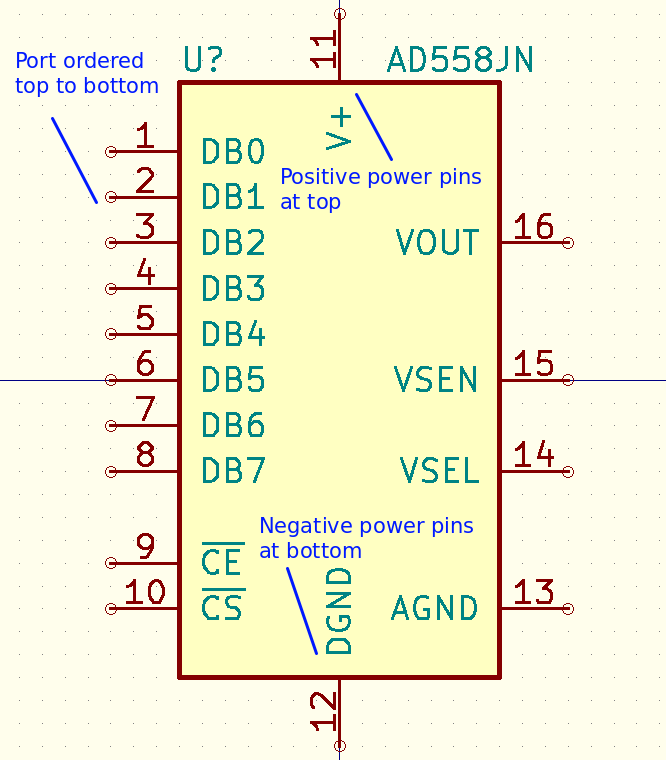

Ports should be ordered from top to bottom

-

Positive power pins should be placed at the top of a symbol

-

Vcc,Vdd,Vin,V+, etc.

-

-

Negative power and ground pins should be placed at the bottom of a symbol

-

GND,Vss,V-, etc. -

Exception Devices intended for power conversion that have both a power in- and output should have the power input pins on the left and the power output pins on the right.

-

-

Input/Control/Logic pins should be placed on the left of a symbol

-

Enable,Sleep -

Iset

-

-

Output/Controlled/Driver pins should be placed on the right of a symbol

-

Alarm -

ChargeFinished -

Q,!Q

-

-

Bus connections like SPI/I²C/.. should be arranged according to library standards (Examples can be found in the wiki, https://gitlab.com/groups/kicad/libraries/-/wikis/Symbole-Bus-Pin-Order)

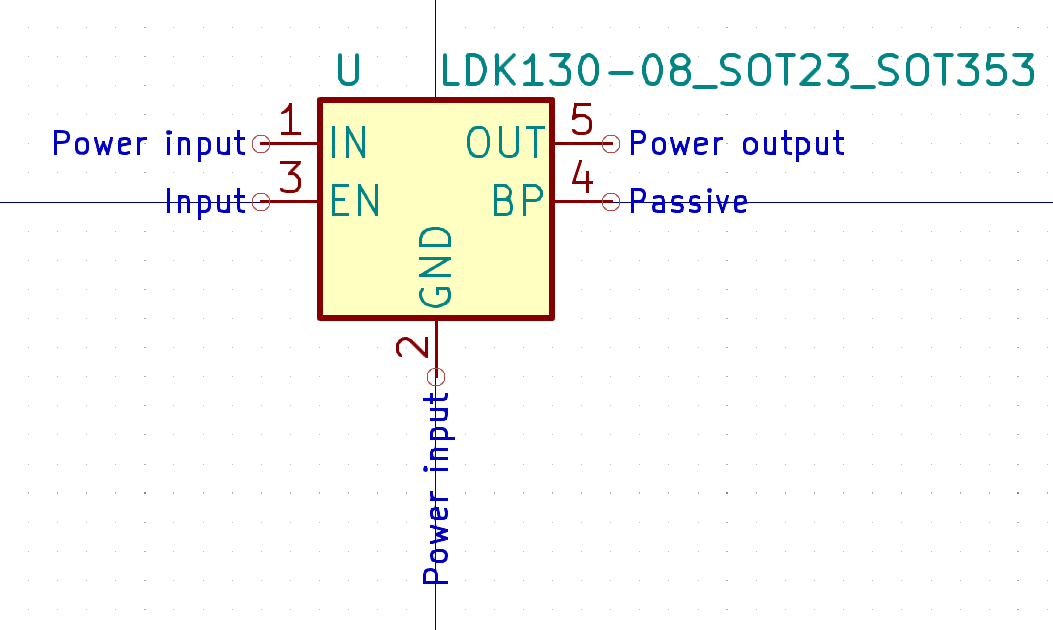

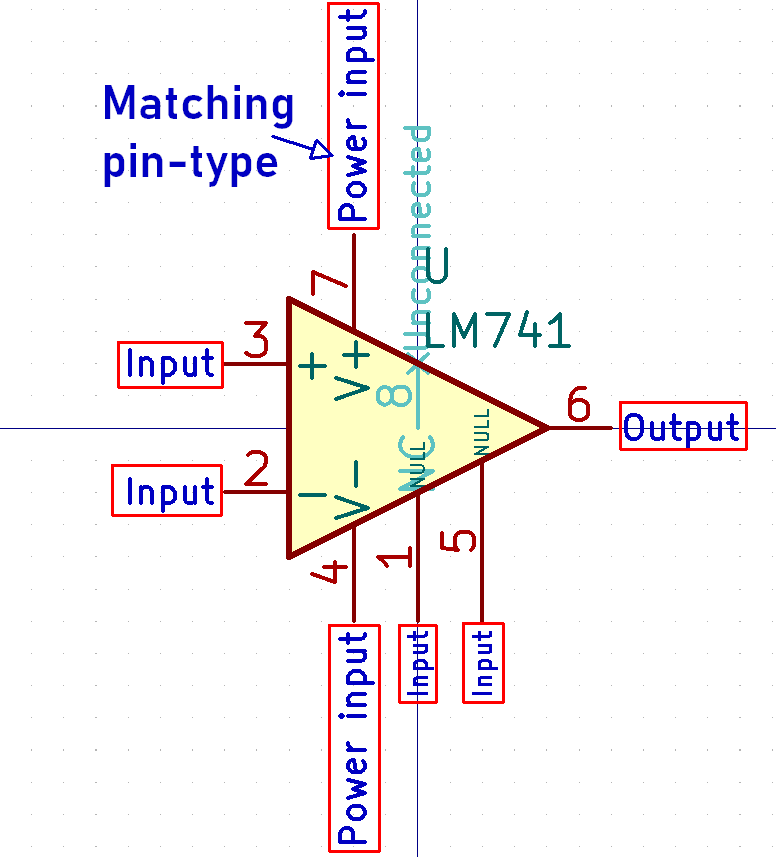

S4.3 Rules for pin stacking

Many symbols have corresponding footprints where multiple physical pins are connected to a single logical net. It is desirable that in such cases the user only has to connect a single pin in the schematic, and it will automatically route to all the physical pins on the PCB. (This is not only done to reduce clutter in the schematic drawing. The main reason is to move some responsibility for correct connections from the circuit designer over to the library.)

KiCad currently has no native method for designating that a particular symbol pin maps to multiple footprint pins. The following guide serves as a workaround for designing such symbols.

In the schematic view, pins that share the same position are considered to be connected by the KiCad routing algorithm. Thus, pins can only be placed in the same location under a very specific set of circumstances:

-

Pins must not be of type

No Connect(these pins should never be connected together) -

Power supply pins must be stacked unless the datasheet specifies the need for decoupling capacitors on every pin.

-

Pins are logically connected in the symbol

-

Pins must have the same name

-

Pins must have the same electrical type

-

One pin in the stack must be visible (all other pins set to invisible)

Special Case: Pins of electrical type [Output, Power Output, Power Input] are special cases.

-

Connecting

OutputorPower Outputpins would result in an ERC error. Output pins that always need to be connected together must therefore be stacked. The invisible pins get the pin typepassivein this case. -

Invisible

Power Inputpins are global labels. This is to be avoided. For this reason the electrical typepassiveis to be used for the invisible pins in such stacks.

S4.4 Pin electrical type

Pin Electrical type should be set to match the appropriate pin function

-

Power and ground pins should be set to either

Power InputorPower Output -

Logic pins should be set according to datasheet requirements

-

Pins with programmable functionality (e.g. MCU I/O ports) should be set to

Bidirectional -

Pins must not be 'double inverted' by assigning the inverting graphical symbol and also having a bar above the name of the pin

S4.5 Pins not connected on the footprint may be omitted from the symbol

Often a component has pins that are not physically connected. Even these pins should be included in the symbol. Refer to the requirements for hidden pins.

However in some cases unconnected pins may be omitted from the schematic symbol.

-

Pins may only be omitted if they are never to be connected under any circumstances

-

Unconnected pins may only be omitted if including them would make the symbol unnecessarily large.

-

If pins are designated

NCbut the datasheet specifies that these must be pulled to ground or otherwise connected to a specific net, then these must be shown on the schematic symbol -

The footprint filter must include the pad count of the footprint if the symbol has omitted pins (see also requirements for footprint filters)

-

BGA?144 -

QFN?20

-

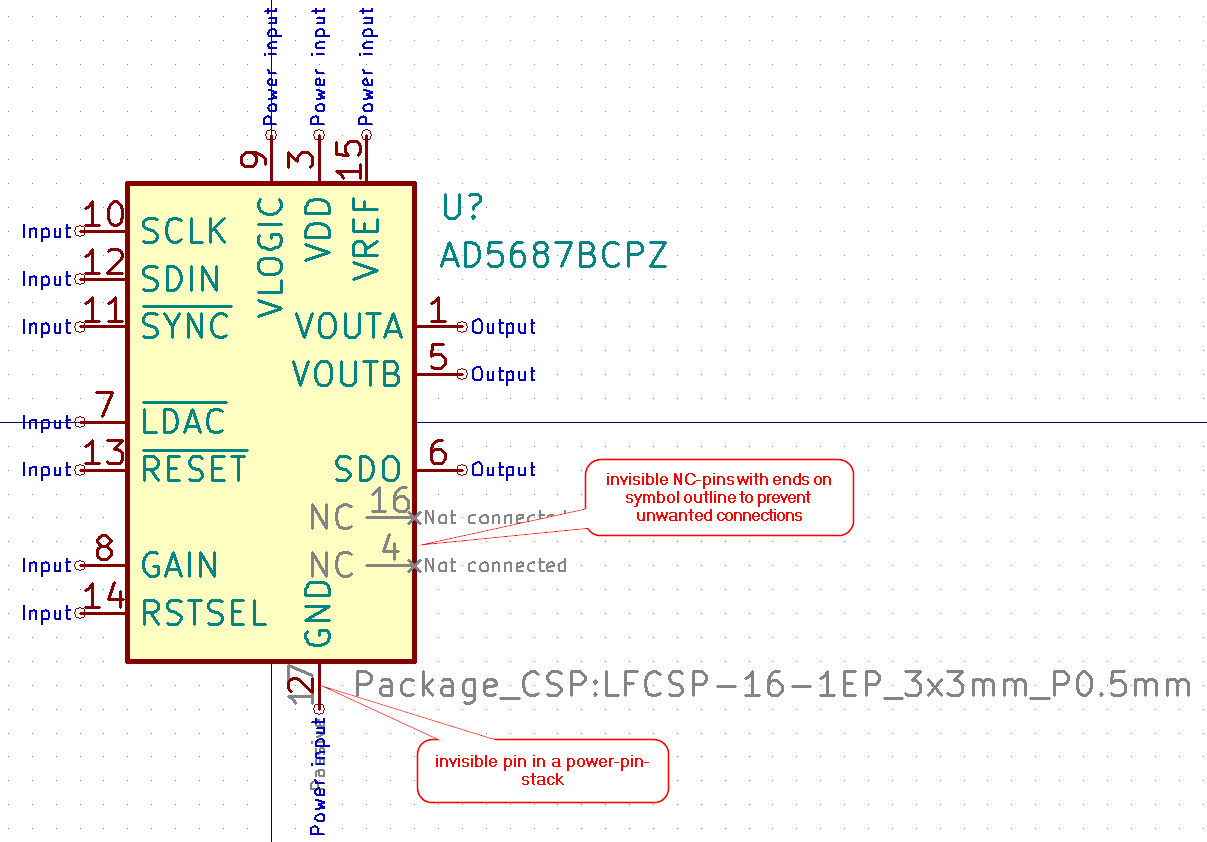

S4.6 Hidden pins

Hidden symbol pins are generally not allowed for schematic symbols. Any connection point must be visible, otherwise unexpected net connections can occur.

Exceptions

-

Power input pins must not be invisible unless used in power symbols (hidden power input pins are global labels). Refer to the requirements for pin stacking

-

Pins that are not intended to be connected must be set to invisible. In this case the electrical type must be

Not Connected. The end of the pin should lie within or on the symbols outline to prevent unwanted connections to the invisible pin (see screenshot below).-

Pins specified as not connected may be shown if they are expected to be connected in a significant number of usecases. (Example: The datasheet suggests them to be connected to ground or some other potential for better EMC behaviour.)

-

-

Invisible pins may be used in a pin stack to allow one-to-many connections. Refer to the requirements for pin stacking

S4.7 Active low pins should be designated using a bar above the symbol name

Rather than selecting the active low graphical pin style, active low pins should be designated using a bar above the pin name.

This provides a cleaner look for the schematic.

To place a line above the pin text, add curly brackets {} around the name, and prefix with the (~) character. In case of a pin name where only a part of it is

active low, and hence, not all of it needs a bar above, e.g. \~{SPD_LED}/GPIO2.

If the pin name given by the manufacturer includes an active low prefix or suffix, it should be removed when adding the bar above it

to avoid negating it twice. For example for nRESET, use ~{RESET}.

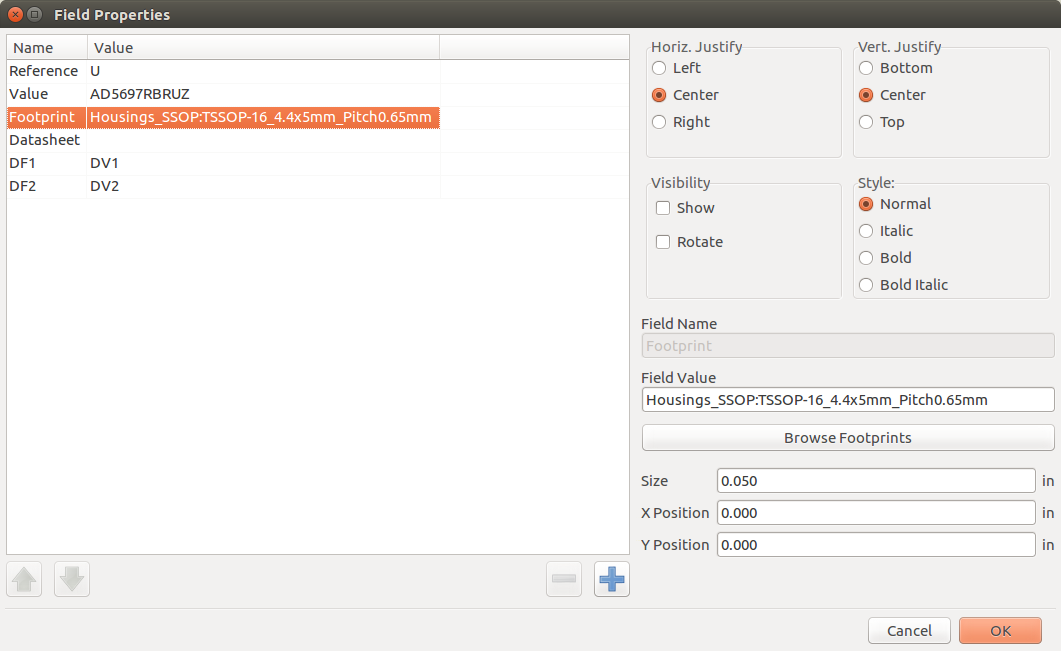

S5 - Footprint Association

S5.1 Symbols with a default footprint link to a valid footprint file

-

For atomic symbols (those with an associated default footprint), the Footprint field must be filled with a valid entry of the format

<footprint_library>:<footprint_name>. -

For generic symbols (those which map to multiple possible footprints), the Footprint field must be left blank

S5.2 Footprint filters must match all appropriate footprints. They should be designed to result in no false suggestions.

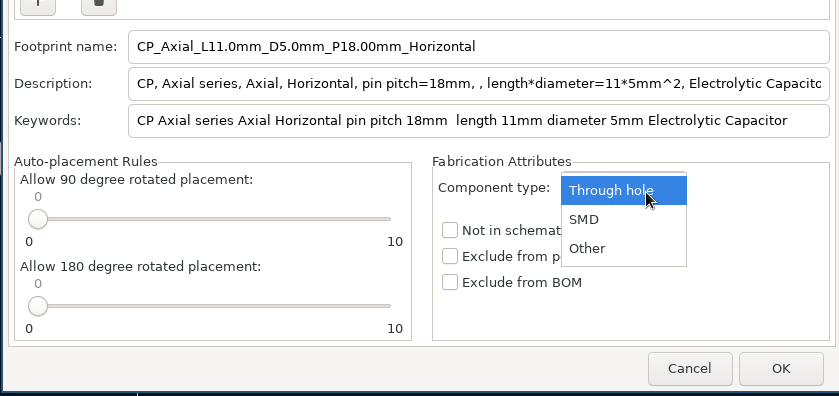

Footprint filters are used to help match appropriate footprints to a given symbol. This is important even for fully specified symbols (symbols with only one matching footprint), as there still may be multiple compatible footprints with different variants or options (e.g. _HandSoldering, _Heatsink, _ThermalVias).

Footprint filters use wildcard pattern matching, and allow the following wildcards:

-

*- Match zero or many characters -

?- Match zero or one characters

The library name can be used as a filter criterium. The delimiter between library and footprint filtering is :

Filter conventions:

-

Filters must end with a

*wildcard to allow matching of modified footprint suffixes -

Filters must match the dimensional information (where required) to be as specific as necessary:

-

DIP*W7.62mm*to matchDIP-22_W7.62mmbut notDIP-22_W9.3mm -

The size of the mask cutout is not included in the filter.

-

Exposed/thermal pad sizes are included in the filter if that is necessary to distinguish between otherwise-ambiguous footprints.

-

-

Filters must not contain the pin count if the pin-count in the symbol matches the pin count in the footprint. In those cases the footprint is matched by KiCad’s pin count filter. If not all pins are present in the symbol (e.g. NC-pins) the pin-count has to be part of the footprint filter (see requirements for NC pins). Then e.g.

SOT?23?5might be used instead of simplySOT?23*to matchSOT-23-5.-

Special pin specifiers are always included. Meaning the specifier for Exposed pads

EP, Mounting padMPand ShieldSHincluding their count must be included if the symbol uses these pins. (Filter for QFN-16-1EP_3x3mm_P0.5mm_EP1.8x1.8mm would beQFN*1EP*3x3mm*P0.5mm*)

-

-

By default, the footprint search does not include the name of the footprint library. To force the library name to be included, add the

:(colon) character to the filter. Text appearing before the:will match the library name. Text appearing after the:will match the footprint name.-

Connector*:*Pitch?1.25mm*will match any footprint with '1.25mm' pitch, only in libraries that begin with the text 'Connector'

-

-

Escape the characters

-and_by replacing them with?.-

SOT?23will matchSOT-23andSOT_23. This gives more flexibility in matching footprint naming.

-

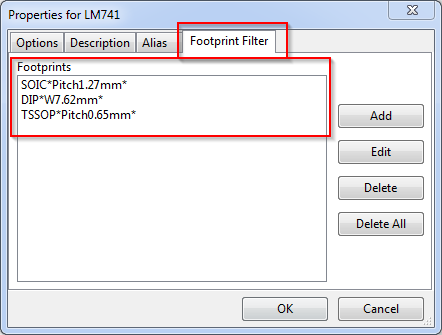

Footprint filters can be set in the Footprint Filter tab in the Symbol Properties window.

S6 - Symbol Metadata

S6.1 Component Reference Designator (RefDes)

The symbol Reference Designator must be filled out appropriately for the particular type of symbol.

The table below provides a list of appropriate RefDes values. If you do not find an appropriate component entry, consult with the KiCad library team.

| Designator | Component Type |

|---|---|

| A | Sub-assembly or plug-in module |

| AE | Antenna |

| BT | Battery |

| C | Capacitor |

| D | Diode |

| DS | Display |

| F | Fuse |

| FB | Ferrite bead |

| FD | Fiducial |

| FL | Filter |

| H | Hardware (mounting screws, etc) |

| J | Jack, fixed part of a connector pair |

| JP | Jumper / link |

| K | Relay |

| L | Inductor, coil, ferrite bead |

| LS | Loudspeaker or buzzer |

| M | Motor |

| MK | Microphone |

| P | Plug, movable part of a connector pair |

| Q | Transistor |

| R | Resistor |

| RN | Resistor network |

| RT | Thermistor |

| RV | Varistor |

| SW | Switch |

| T | Transformer |

| TC | Thermocouple |

| TP | Test point |

| U | Integrated circuit (IC) |

| Y | Crystal / oscillator |

| Z | Zener diode |

S6.2 Symbol fields and metadata filled out as required

-

Reference field is selected appropriately for the symbol and is visible

-

Value field contains the name of the symbol and is visible

-

Footprint field contains footprint link for fully specified symbols and must be invisible

-

The footprint field must be empty for generic symbols

-

-

Datasheet entry is filled out, and is invisible

-

For generic symbols, the datasheet field should be a tilde (

~)

-

-

KLC Exception properties are allowed start with "KLC_" and are allowed, but they should only be added after a discussion with a librarian.

-

The symbol contains no other custom fields

Additional documentation is provided via two other fields:

-

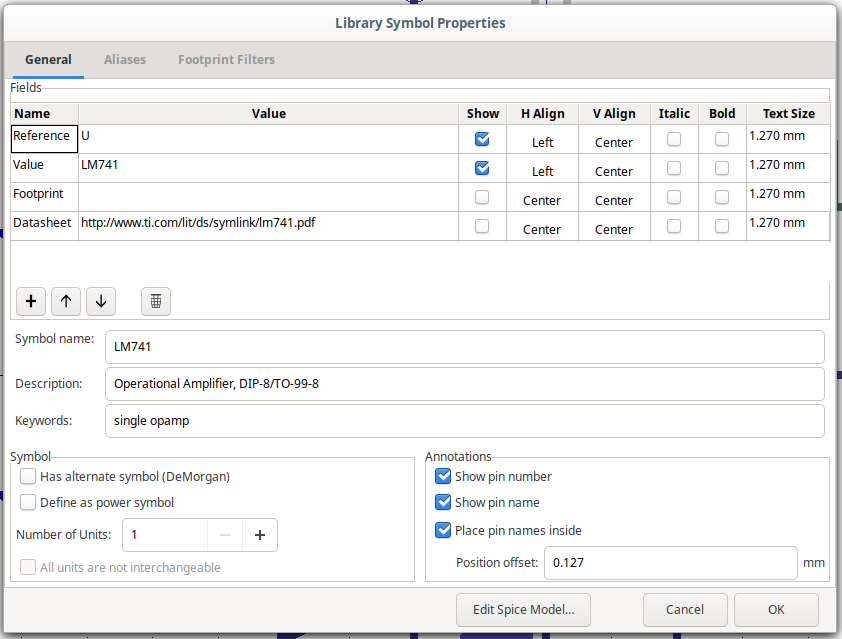

Description field contains comma-separated device information

-

For symbols with a default footprint, the simplified footprint name should be appended to the description e.g.

SOIC-8 -

Part name should not be duplicated in the description field

-

-

Keywords field contains space-separated keyword values. These values are used to assist in part searching and should be selected to assist end-users in finding suitable parts

-

Keywords should contain typical aliases for words, Example: Description contains

Operational amplifier⇒ keywords should containopamp. -

Keywords should not include filler words. Example

positive negativeinstead ofpositive and negative -

Any single word which already appears in the description field, should not be included in the keywords field. Example: Description =

50mA Low-Dropout voltage regulator, QFN-16⇒ Keywords could includeLDObut notregulatororQFN -

In case phrases (multiple words which belong together) are used in the keywords, the must not be separated by spaces, but by a dash. Example:

voltage-regulatorinstead ofvoltage regulator -

Words which are prefixes of other words from either the Keywords or Description field should not appear in the keywords. Example: Description =

FPGA with Brown-Out detection, QFN-16⇒ Keywords could includebrownoutbut notbrown

-

S7 - Special Symbols

S7.1 Power symbols

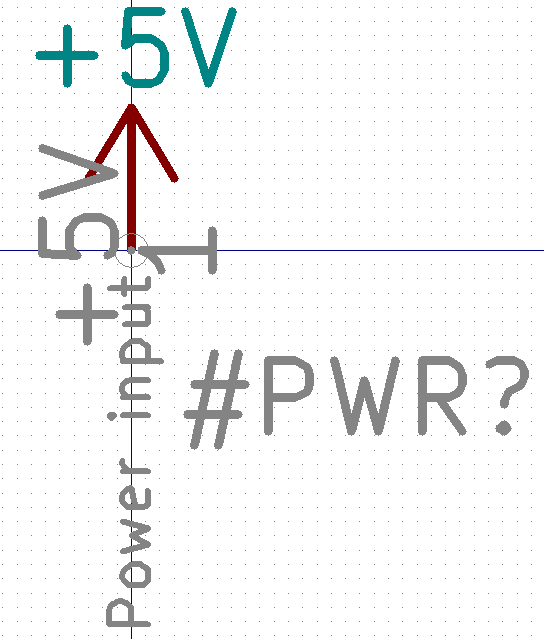

Power symbols are special symbols in KiCad, used to designate global nets for power connections.

-

Reference Designator must be set to

#PWR -

Power symbols must contain exactly one pin, which is set to visible. Note: Before KiCad 8, power symbol pins needed to be invisible, but in KiCad 8 and later they should be visible

-

Electrical pin type must be set to

Power Input -

Pin name must be set to

~ -

Value field must match the symbol name

-

Checkbox

Define as power symbolmust be checked

The example image below demonstrates the requirements as listed above:

S7.2 Graphical symbols

Graphical symbols represent "drawing" rather than physical components. They may or may not correspond to an object on the PCB.

For all graphical symbols:

-

Symbol name must be set to invisible

-

Graphical symbols must not contain any pins

-

The option

exclude from BOMmust be checked

For symbols that may appear on a PCB (e.g. an OSHW logo), the default is to set them up such that a footprint can easily be assigned:

-

Reference Designator must be set to

SYMand must be visible -

Most graphical symbols match multiple footprints (e.g. different sizes, layers or styles).

-

Set footprint filters appropriately

-

Only add a default footprint if there is unambiguously only one possible suitable footprint.

-

-

The option

exclude from boardmust not be set

For symbols that will never appear on the PCB:

-

Reference Designator must be set to

#SYMand must be invisible -

The option

exclude from boardmust be checked

Example of a symbol which may have a footprint:

Example of a symbol which will never have a footprint:

Footprint Guidelines

The following guidelines apply to PCB footprints and footprint libraries.

F1 - Footprint Libraries

F1.1 Footprint libraries are categorized by function

Footprints are grouped into libraries (directories with .pretty extension) based on their primary function. As an extension of this, footprint libraries should be named based on this same functionality.

Library names must be defined based on the priority list below, with each element separated by the underscore (_) character:

-

Function (e.g.

Conn,Capacitor) -

Sub-function (e.g.

HDMI,USB) -

Tertiary qualifier (e.g.

RightAngle,SMD) -

Manufacturer name (e.g.

Texas,Microchip) -

Footprint series name (e.g.

MicroFit) -

Extra library descriptors as required

Note: Some of the elements listed above may be omitted if not required.

Example footprint library names:

-

Conn_USB_SMD- Surface mount USB connectors -

Conn_Molex_MicroFit- Molex MicroFit series rectangular connectors -

Capacitor_Tantalum_SMD- Surface mount Tantalum capacitors

F1.2 Connector footprint libraries

Categorizing connectors by function can prove difficult as many connectors can be used in a wide variety of applications.

Therefore, categorization of connector footprints is given special consideration as detailed below:

-

Connectors are grouped firstly by their primary function (where such a function exists). Examples of primary function include:

-

Conn_USB -

Conn_HDMI -

Conn_Ethernet

-

-

When primary function libraries become too large, they can be split by sub-function or by manufacturer

-

Conn_USB_Molex -

Conn_DSUB_HighDensity

-

-

For connectors without a specific function, then connectors are grouped by their mechanical type:

-

Conn_Barrel -

Conn_DIN -

Conn_DSUB -

Conn_PinHeader -

Conn_PinSocket -

Conn_Rectangular

-

-

Connector libraries can be further split by another qualifier:

-

Conn_PinHeader_2.54mm -

Conn_PinHeader_1.27mm

-

-

Connector libraries can also be split by manufacturer and series, for multi-purpose connectors

-

TerminalBlock_Phoenix_MKDS -

TerminalBlock_Phoenix_PT -

TerminalBlock_Wago -

Conn_JST -

Conn_Hirose_DF13

-

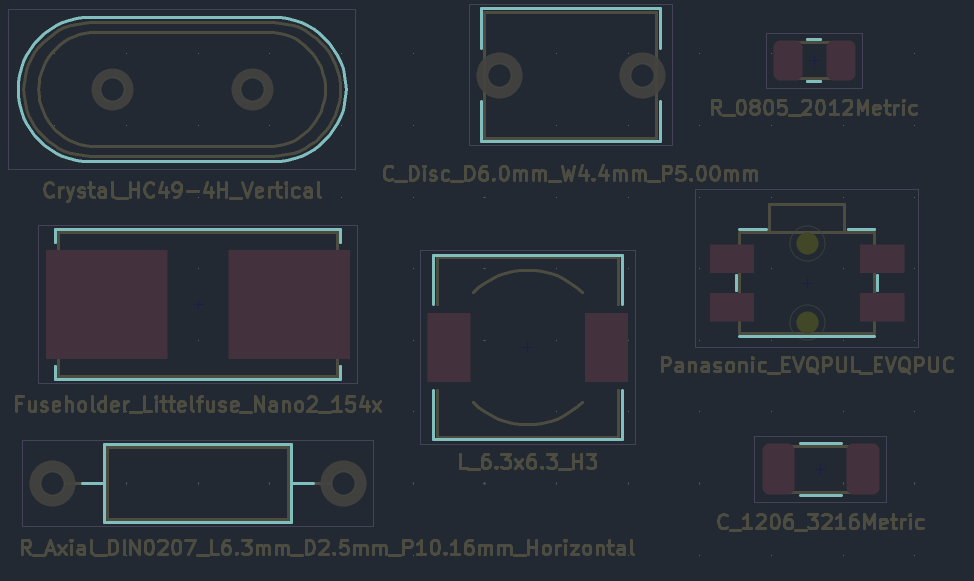

F2 - General Footprint Naming Guidelines

F2.1 General footprint naming conventions

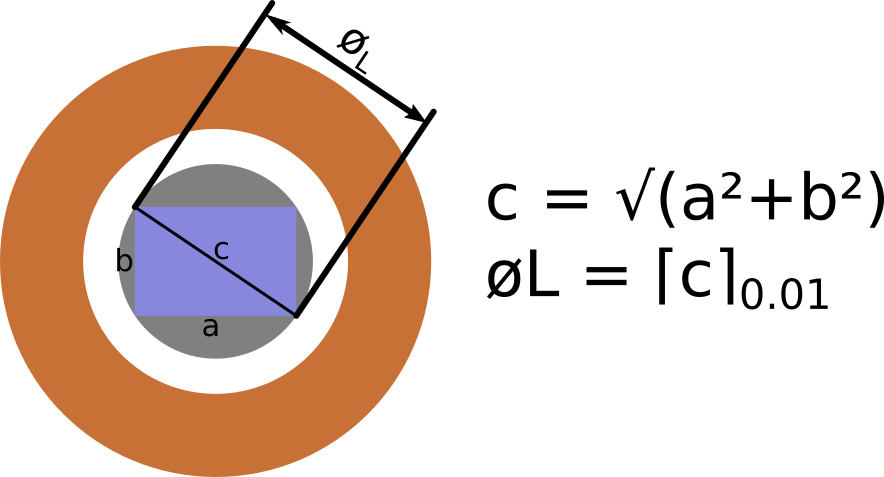

Each footprint is a .kicad_mod file (stored within a .pretty directory). The naming convention for a given footprint depends largely on the type of footprint, however a general guide is presented below:

-

Specific package type is written first, e.g.

-

QFN- Quad Flat No-Lead package -

C- Capacitor

-

-

Package name and number of pins are separated by a hyphen

-

TO-90 -

QFN-48 -

DIP-20

-

-

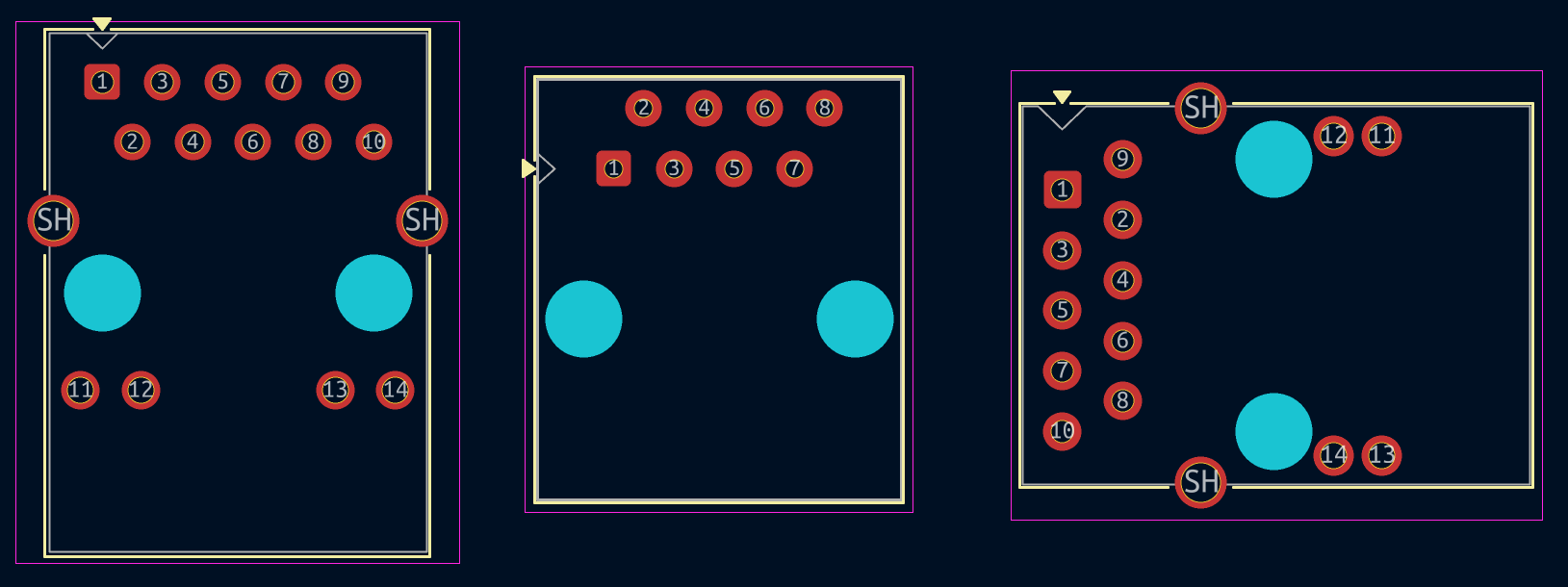

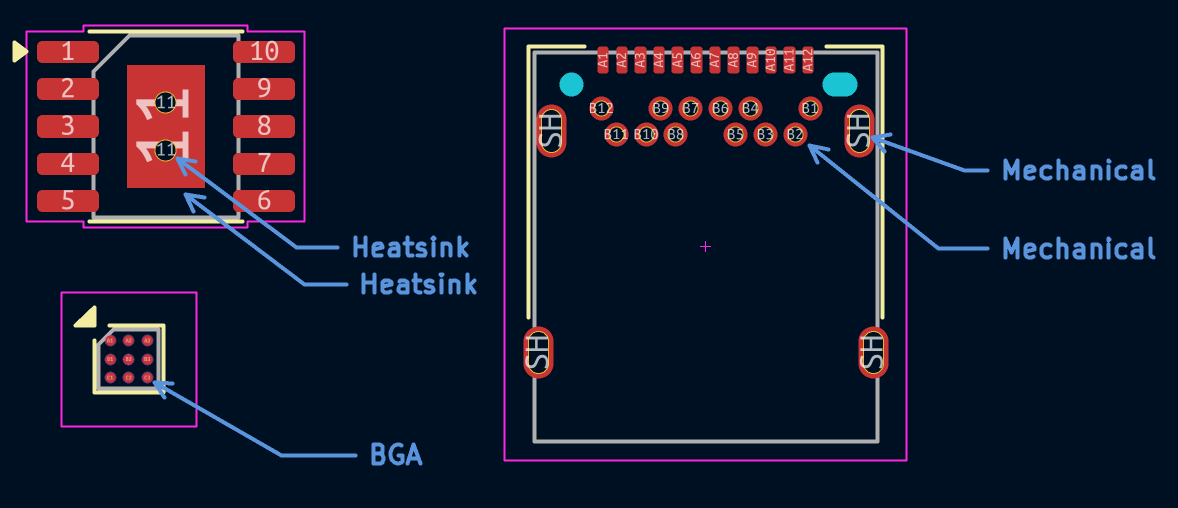

Packages with special pads add an identifier to the pin count field separated by a hyphen

-

The field includes the count of uniquely numbered pads of this type.

-

For exposed pads (large copper pad below the part)

[count]EP -

For shield pads

[count]SH(Unless such a pin is already expected for the part. An example would be a HDMI connector.) -

For pads connecting pure mechanical mounting leads

[count]MP

-

-

Examples from the library.

-

DFN-6-1EP_2x2mm_P0.5mm_EP0.61x1.42mm -

Samtec_LSHM-110-xx.x-x-DV-S_2x10-1SH_P0.50mm_Vertical -

Molex_PicoBlade_53261-0271_1x02-1MP_P1.25mm_Horizontal

-

-

-

Unique fields (parameters) in the footprint name are separated by

_character. -

Package dimensions are specified as

lengthxwidth(and optionallyheight)-

3.5x3.5x0.2mm -

1x1in -

If necessary for clarity, footprint body dimensions may be prefixed with a leading

B

-

-

Pin layout

-

1x10 -

2x15

-

-

Pitch is specified with a leading

P:-

P1.27mm- 1.27mm pitch -

P5.0mm- 5.0mm pitch

-

-

Modifiers to standard footprint values

-

Drill1.25mm -

Pad2.4x5.2mm

-

-

Orientation e.g.

Horizontal,Vertical -

Any modification to the original footprint, indicated by appending the reason

-

_HandSoldering -

_ThermalVias -

_CircularHoles

-

Not all of the fields defined above are strictly required for a particular footprint. Additional fields may also be added as needed.

F2.2 Footprint naming field prefixes

A footprint name has to convey a lot of information to clearly specify the purpose and parameters of the footprint. Some fields in footprint names are common to many footprints and can be shortened using special abbreviations.

Not all footprints will require the use of these abbreviations - they are provided as a method of standardising the manner in which footprint parameters are called out when encountered.

In many cases, the major dimensions (x/y/z) of a footprint may be specified without a prefix, as the body dimensions are assumed to have the greatest priority in the footprint name. Therefore, the "3.2x5.7mm" part of the example name below requires no 'B' prefix, and is not required to be written as "B3.2x5.7mm".

e.g. SOIC-8_3.2x5.7mm_P1.27mm

In cases where potential conflicts exist, however, the body dimensions must be explicitly named with the prefix B.

Refer to the table below for accepted prefix abbreviations.

| Prefix | Field Description | Notes |

|---|---|---|

| B | Body dimensions |

|

| D | Diameter |

|

| H | Height |

|

| L | Length |

|

| O | Offset |

|

| W | Width |

|

| EP | Exposed pad dimensions |

|

| P | Pad pitch |

|

| T | Thickness | Component thickness, where appropriate |

Examples:

-

LQFP-32_4x4x1.1mm_P1.65mm- LQFP package, 32 pins, 4x4mm body, 1.1mm height, 1.65mm pitch -

CP_Radial_D4.5mm_P2.5mm_H10mm- Radial polarized capacitor, 4.5mm diameter, 2.5mm pitch, 10mm height

If the parameter is not found in the table above, the name of the parameter should be entered in full.

Following is a list of examples of (non-abbreviated) parameter names used in footprint naming

| Prefix | Field Description |

|---|---|

| Ball | BGA Ball diameter |

| CenterHeight | Height of centerline of a component above the board surface. For example, elevated connectors. Usually defined explicitly in the datasheet. |

| Clearance | Clearance between pin rows |

| Drill | Drill diameter |

| Layout | Specific footprint layout e.g. Layout3x7 for a BGA with 21 balls arranged in 3 columns and 7 rows |

| Lead | Lead dimensions |

| Mask | Custom soldermask dimensions |

| Pad | Custom pad dimensions |

| StackHeight | The height that a component contributes to a mated stack height, above the board surface. Usually defined explicitly in the datasheet. |

| Tab | Tab dimensions |

F2.3 Manufacturer specific version of generic footprints

If a manufacturer footprint deviates from the "standard" footprints available, then this should be added to the library and designated as manufacturer-specific.

-

If a footprint is specific to a single manufacturer, this must be indicated by prepending the manufacturer name and MPN to the footprint name.

-

Texas_S-PVQFN-N48_

-

-

Sometimes the component datasheet will have specific requirements which do not conform to KLC requirements. A common example is specific requirements for the shape of stencil (solder paste layer).

In such cases, the KLC requirements can be superseded by the datasheet requirements, at the discretion of the KiCad library team.

F2.4 Footprint naming for non-standard pin numbering

Generally, a footprint should include a field of the format <pkg>-<pincount>, e.g.

-

SOIC-8 -

QFN-24

In the majority of cases, the pin quantity is self explanatory and is sufficient to describe the number of pins on the symbol.

However there may be cases where this numbering is insufficient. Where the number of footprint pins does not match the number of package pins, exceptions must be made.

Exception: Omitted pins, missing pin numbers are skipped

Example: LTC3638

The LTC3638 comes in an MSOP-16 package which has four missing pins, for increased voltage isolation.

In this case, the numbers for the missing pins are skipped and the normal pin numbers are assigned to the remaining pins.

To indicate this, the footprint should be named as follows:

PKG-<xx>-<yy> where:

-

xx= number of remaining pins -

yy= number of remaining pins + number of removed pins

In the LTC3638 example above, this would result in:

MSOP-12-16

The footprint pads should be numbered like so:

F2.5 Footprint naming conventions for specific components

Footprint naming is sufficiently complex that a general rule is not enough to fully define a naming scheme that fits the wide range of footprints.

F3 - Specific Footprint Naming Guidelines

F3.1 SMD chip package naming conventions

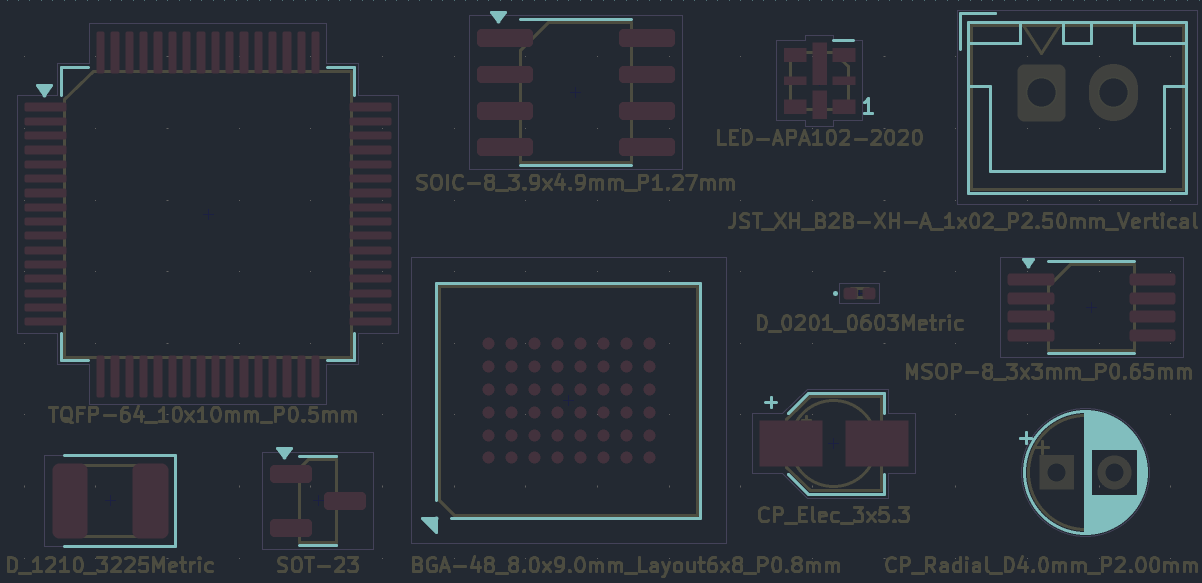

The following footprint naming conventions should be used as examples for naming SMD chip package footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

- Prefix - Device type

- Imperial size - Imperial case size (Optional)

- Metric size - Metric case size (Optional)

- Modifiers - Modifiers to footprint if non standard (Optional)

- Options - Extra footprint options (Optional)

Example:

Notes:

The prefix is determined by the default reference designator of the device, e.g.

-

Capacitor =

C -

Capacitor (polarised) =

CP -

Resistor =

R -

Diode =

D

Case size codes:

| Imperial Code | Metric Code | Size Imperial | Size Metric |

|---|---|---|---|

01005 |

0402 |

0.0157 in × 0.0079 in |

0.4 mm × 0.2 mm |

0201 |

0603 |

0.024 in × 0.012 in |

0.6 mm × 0.3 mm |

0402 |

1005 |

0.039 in × 0.020 in |

1.0 mm × 0.5 mm |

0603 |

1608 |

0.063 in × 0.031 in |

1.6 mm × 0.8 mm |

0805 |

2012 |

0.079 in × 0.049 in |

2.0 mm × 1.25 mm |

1008 |

2520 |

0.098 in × 0.079 in |

2.5 mm × 2.0 mm |

1206 |

3216 |

0.126 in × 0.063 in |

3.2 mm × 1.6 mm |

1210 |

3225 |

0.126 in × 0.098 in |

3.2 mm × 2.5 mm |

1806 |

4516 |

0.177 in × 0.063 in |

4.5 mm × 1.6 mm |

1812 |

4532 |

0.18 in × 0.13 in |

4.5 mm × 3.2 mm |

1825 |

4564 |

0.18 in × 0.25 in |

4.5 mm × 6.4 mm |

2010 |

5025 |

0.197 in × 0.098 in |

5.0 mm × 2.5 mm |

2512 |

6332 |

0.25 in × 0.13 in |

6.3 mm × 3.2 mm |

2920 |

7451 |

0.29 in × 0.20 in |

7.4 mm × 5.1 mm |

F3.2 Resistor naming conventions

The following footprint naming conventions should be used as examples for naming resistor footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

Axial Resistors

- Length - Resistor body length

- Diameter - Body diameter

- Pitch - Lead spacing

- Modifiers - Modifiers to footprint specifications (Optional)

- Orientation - Resistor orientation (Vertical / Horizontal) (Optional)

- Options - Extra footprint options (Optional)

Example:

F3.3 Capacitor naming conventions

The following footprint naming conventions should be used as examples for naming capacitor footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

SMD Chip Capacitor

- C/CP - Capacitor style (polarised or non-polarised)

- Imperial size - Imperial case size (Optional)

- Metric size - Metric case size (Optional)

- Modifiers - Footprint modifiers if non standard (Optional)

- Options - Footprint options (Optional)

Example:

Notes:

-

At least one case size (either imperial or metric) must be specified

-

Metric case size must have the suffix

Metric

SMD Tantalum Capacitor

- Metric size - EIA metric size code

- Size code - Letter size code including naming standard ([Standard]-[Letter])

- Modifiers - Footprint modifiers if non standard (Optional)

- Options - Footprint options (Optional)

Example:

| EIA Metric size | Body size (XxYxZ) | Kemet Code | AVX Code |

|---|---|---|---|

1608-08 |

1,6 x 0,8 x 0,8 mm |

— |

J |

1608-10 |

1,6 x 0,85 x 1,05 mm |

— |

L |

2012-12 |

2,05 x 1,35 x 1,2 mm |

R |

R |

2012-15 |

2,05 x 1,35 x 1,5 mm |

— |

P |

3216-10 |

3,2 x 1,6 x 1,0 mm |

I |

K |

3216-12 |

3,2 x 1,6 x 1,2 mm |

S |

S |

3216-18 |

3,2 x 1,6 x 1,8 mm |

A |

A |

3528-12 |

3,5 x 2,8 x 1,2 mm |

T |

T |

3528-15 |

3,5 x 2,8 x 1,5 mm |

— |

H |

3528-21 |

3,5 x 2,8 x 2,1 mm |

B |

B |

6032-15 |

6,0 x 3,2 x 1,5 mm |

U |

W |

6032-20 |

6,0 x 3,2 x 2,0 mm |

— |

F |

6032-28 |

6,0 x 3,2 x 2,8 mm |

C |

C |

7343-15 |

7,3 x 4,3 x 1,5 mm |

W |

X |

7343-20 |

7,3 x 4,3 x 2,0 mm |

V |

Y |

7343-30 |

7,3 x 4,3 x 3,0 mm |

— |

N |

7343-31 |

7,3 x 4,3 x 3,1 mm |

D |

D |

7343-40 |

7,3 x 4,3 x 4,0 mm |

Y |

— |

7343-43 |

7,3 x 4,3 x 4,3 mm |

X |

E |

7360-38 |

7,3 x 6,0 x 3,8 mm |

E |

— |

7361-38 |

7,3 x 6,1 x 3,8 mm |

— |

V |

7361-438 |

7,3 x 6,1 x 4,3 mm |

— |

U |

SMD Electrolytic Capacitor

- Manufacturer - Manufacturer name (Optional)

- X - Case size in x dimension

- true - Case size in y dimension

- [Height] - Case height (Optional)

- [Pitch] - Lead spacing (Optional)

- [Modifiers] - Footprint modifiers if non-standard (Optional)

- [Options] - Footprint options (Optional)

Example:

THT Capacitor

- C/CP - Capacitor polarisation

- Style - Capacitor case style (see notes below)

- Case size - Body length (Optional)

- Diameter - Case diameter (Optional)

- Width - Body width (Optional)

- Pitch - Lead spacing

- Modifiers - Footprint modifiers if non-standard

- Options - Footprint options (Optional)

Example:

Notes:

-

There are different capacitor styles available:

-

Axial: Cylindrical body with axial lead attachment.

-

Radial: Cylindrical body, both leads enter at same end.

-

Disc: Disc shaped body (sometimes enclosed), leads enter tangent to the inner disc

-

Rect: Box shaped body (Bottom face in contact with the board)

-

-

Body size:

-

For Axial body styles: L[length]_D[diameter]

-

For Radial body style: D[diameter]{_H[height]}

-

For Disc body style: D[diameter]_W[width]{_H[overall height]}

-

For box shaped body styles: [X]x[Y]{x[Z]}

-

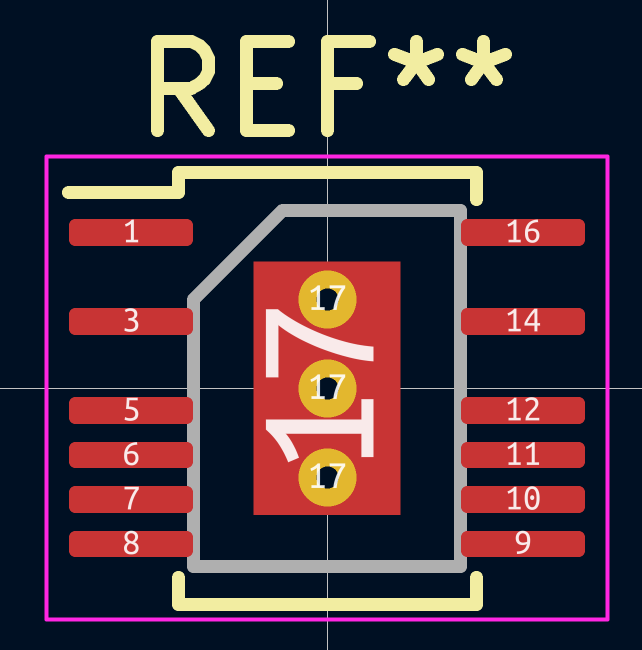

F3.4 SMD IC package naming conventions

The following footprint naming conventions should be used as examples for naming SMD IC package footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

Gullwing Packages

The format below provides a guide for naming Gullwing IC packages.

Examples:

-

SOIC

-

SOP

-

QFP

-

J-Lead

- PKG - Package name

- Pin count - Number of (unique) pins

- EP Qty - Number of exposed pads under the device (if greater than zero) (Optional)

- X - Major dimension of part on x axis

- Y - Major dimension of part on y axis

- Z - Major dimension of part on z axis (Optional)

- Pitch - Lead pitch

- Modifiers - Footprint modifiers (Optional)

- Options - Extra footprint options (Optional)

Example:

Notes:

-

[

PKG] - refers to the name most commonly used in the industry. Generally this implies JEDEC naming but some other standard may be used as required. -

[

Pin count] - the number of uniquely numbered pads (excluding any exposed pads under the device) -

[

Modifiers] - may vary for individual IC footprint types. Includes:-

Clearance

-

Lead size

-

Pad size

-

Exposed pad size

-

Soldermask expansion

-

No-Lead Packages

Examples:

-

DFN

-

QFN

-

LCC

- PKG - Package name

- Pincount - Number of (unique) pins

- EP Qty - Number of exposed pads under the device (if greater than zero) (Optional)

- X - Major dimension of part on x axis

- Y - Major dimension of part on y axis

- Z - Major dimension of part on z axis (Optional)

- Pitch - Lead pitch

- Modifiers - Footprint modifiers (Optional)

- Options - Extra footprint options (Optional)

Example:

Notes:

-

The lead length is the nominal lead length for which the footprint is designed

-

Optionally the nominal lead width can also be provided

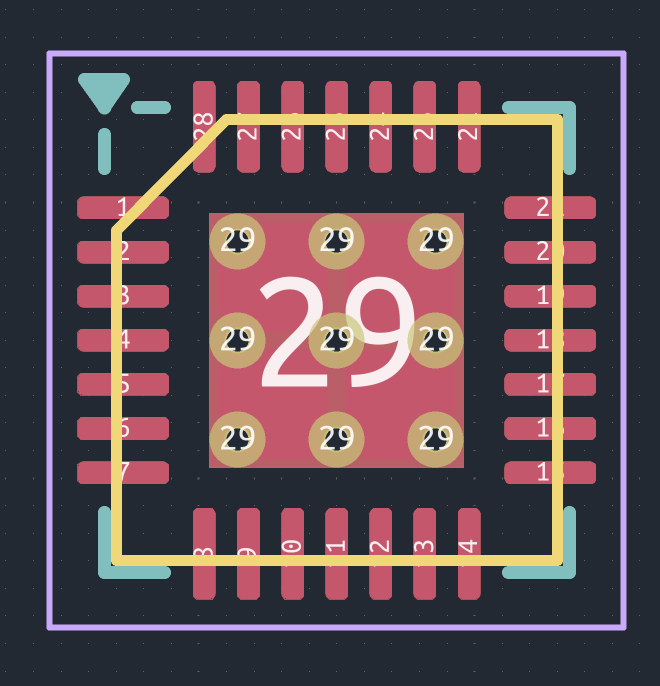

Ball Grid Array Packages

- PKG - Package name

- Pincount - Number of (unique) pins

- X - Major dimension of part on x axis

- Y - Major dimension of part on y axis

- Z - Major dimension of part on z axis (Optional)

- Columns - Number of ball columns

- Rows - Number of ball rows

- Pitch X - Ball pitch in x direction

- Pitch Y - Ball pitch in y direction (if different from x direction (Optional)

- Ball - Ball diameter

- Pad - Pad diameter

- NSMD/SMD - Solder Mask Defined or Non Solder Mask Defined

- Modifiers - Footprint modifiers (Optional)

- Options - Extra footprint options (Optional)

Example:

Notes:

-

For BGA simply providing the pin count is not sufficient. It is also necessary to provide the number of [

Columns] (x direction) and [Rows] (y direction). -

Some BGA packages have different pitch in x and y directions. If this is the case then both [

Pitch] dimensions need to be provided -

The [

Ball] diameter for which the footprint is designed needs to be provided -

[

NSMD/SMD]-

NSMD means the footprint is designed for

non solder mask defined(mask cutout is larger than copper pad) -

SMD means the footprint is designed for

solder mask defined(mask cutout is smaller than copper pad)

-

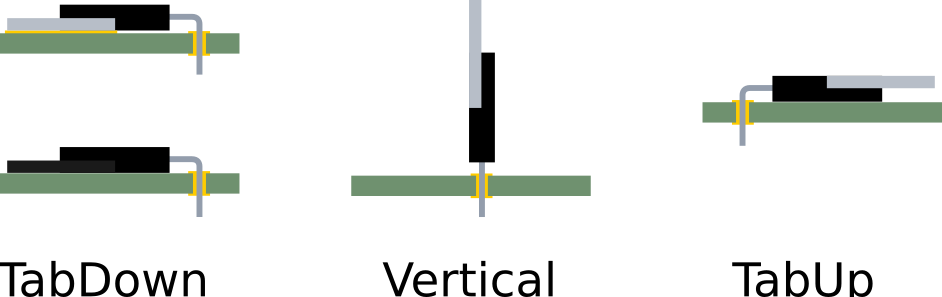

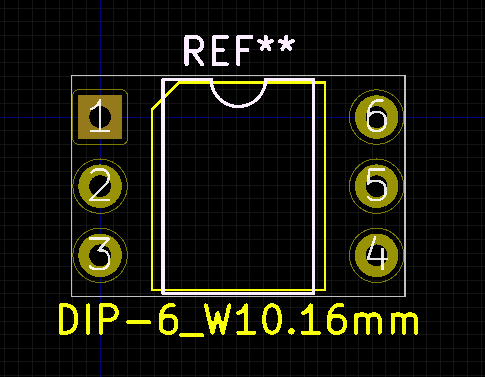

F3.5 THT IC package naming conventions

The following footprint naming conventions should be used as examples for naming THT IC package footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

Through Hole Packages (DIP)

- PKG - Package name

- Pincount - Number of (unique) pins

- X - Major dimension of part on x axis

- Y - Major dimension of part on y axis

- Z - Major dimension of part on z axis (Optional)

- Lead span - Distance between leads

- Pitch - Lead pitch

- Modifiers - Modifiers to footprint specifications

- Options - Extra footprint options (Optional)

Example:

Notes:

-

Drill size (if specified) must be given in

mm

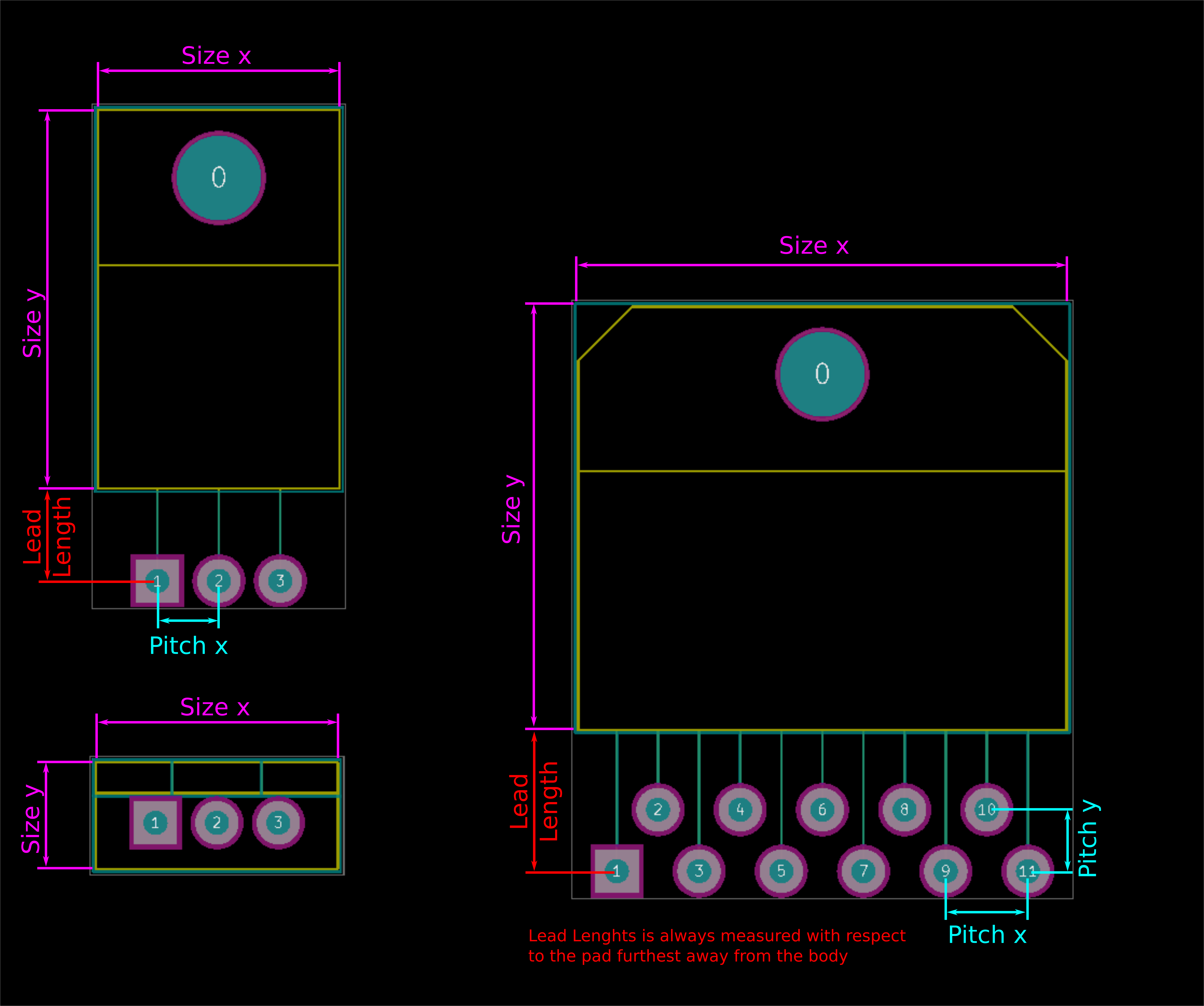

Through Hole Packages (TO)

- PKG - Package name

- Pincount - Number of (unique) pins

- X - Major dimension of part on x axis (Optional)

- Y - Major dimension of part on y axis (Optional)

- Z - Major dimension of part on z axis (Optional)

- Lead span - Distance between leads (Optional)

- Pitch x - Lead pitch in x dimension (Optional)

- Pitch y - Lead pitch in y dimension (if different from x dimension) (Optional)

- Stagger - Pin staggering options (Optional)

- Modifiers - Modifiers to footprint specifications (Optional)

- Orientation - Component orientation (see notes below)

- Options - Extra footprint options (Optional)

Example:

Notes:

-

Drill size (if specified) must be given in

mm -

Orientationcan be chosen from:-

Vertical

-

TabDown

-

TabUp

-

-

Staggercan be chosen from:-

StaggerOdd (odd pins are further from component body)

-

StaggerEven (even pins are further from component body)

-

Size Parameter:

Orientation:

F3.6 Connector naming conventions

The following footprint naming conventions should be used as examples for naming connector footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

Conventions for Connectors

Connector footprints are extremely diverse and the naming conventions for connectors can be complicated. This section details some examples of naming schemes for various connector types. While there are variations between connectors, the general format for naming connectors is as follows:

- Series - Generic series name (Optional)

- Subseries - Series secondary identifier (Optional)

- Pins - Pin count (Optional)

- MPN - Manufacturer specific identifier (Optional)

- Pin layout - Pin configuration, specific to connector type (Optional)

- Pitch - Pin pitch, if not implied by connector standard (Optional)

- Modifiers - Modifiers to connector specifications (pad size, etc) (Optional)

- Orientation - Orientation of connector relative to board (Optional)

- Options - Extra footprint options (Optional)

Notes:

-

[

Series] - a versatile field which could contain:-

Functional description (e.g.

USB) -

Connector type (e.g.

PinHeaderorTerminalBlock) -

Industry standard (e.g.

DSUB-15) -

Manufacturer specific series (e.g.

Hirose_DF13)

-

-

[

MPN] (manufacturer part number) - uniquely identifies a connector according to that manufacturer’s internal naming conventions -

[

Pin layout] - dependent on the connector type-

Single row connectors: 1x[

number of pins] -

Multi row connectors with equal number of pins in each row: [

number of rows]x[number of pins per row] -

Other connectors: [

number of rows]Rows_[number of pins overall]Pins -

Connectors for standardized interfaces do not need to include the pin configuration information (e.g. USB)

-

-

Number format:

-

[

number of rows] number of rows no leading zero. -

[

number of pins per row] and [number of pins] two digit number with leading zero. (can have more digits for connectors with > 99 pins)

-

-

[

Pitch] - if the connector standard does not imply the pin pitch, then this field is required -

[

Modifiers] - multiple fields may be added here, detailing modifications or devations from the standard footprint design. Examples include:-

Pad size variation

-

Drill size variation

-

-

[

Orientation] - The orientation of the connector with reference to the board plane

-

[

Options] - Extra footprint options

In addition to these conventions, additional schemes are employed for specific connector types - these are detailed below.

Connectors for Specific Functions

Many connectors are designed for specific functions (e.g. USB, HDMI, SD-Card, etc). In these cases, specific naming conventions should be followed:

- Function - Functional purpose of the connector

- Standard - Standard to which the connector complies, if applicable (Optional)

- Size - Connector size (e.g. Micro/Mini) (Optional)

- Type - Connector sub-type (e.g. A/B/C) (Optional)

- MAN - Manufacturer name (Optional)

- MPN - Manufacturer part number (Optional)

- Modifiers - Footprint modifiers (Optional)

- Orientation - Connector orientation (Optional)

- Options - Extra footprint options (Optional)

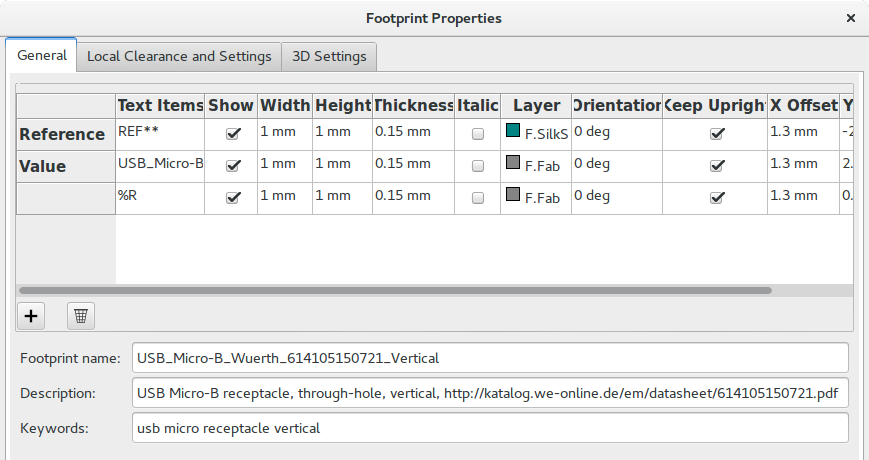

Example:

Notes:

-

Some examples of functional connector naming are provided below:

-

USB_Micro-B_Wuerth_614105150721_Vertical_CircularHoles -

HDMI_Micro-D_Molex_46765-2x0x -

MicroSD_Wuerth_WR-CRD_693072010801

-

-

In most cases, pin layout does not need to be explicitly specified

Connectors with Standardised Shape

Many connectors are provided by multiple manufacturers in an industry standard package or physical layout. These connectors should use the accepted industry naming at the beginning of the footprint name:

- Standard - Generic connector standard (see notes below)

- Pins - Number of pins

- Series modifier - Series Modifier (see notes below)

- MAN - Manufacturer name (Optional)

- Series - Manufacturer series name (Optional)

- MPN - Manufacturer part number (Optional)

- Pin layout - Pin configuration, if not fully defined by applicable standard (Optional)

- Pitch - Pin pitch, if not fully defined by applicable standard (Optional)

- Modifiers - Footprint modifier field(s) (Optional)

- Orientation - Connector orientation (if multiple options exist) (Optional)

- Options - Extra footprint options (Optional)

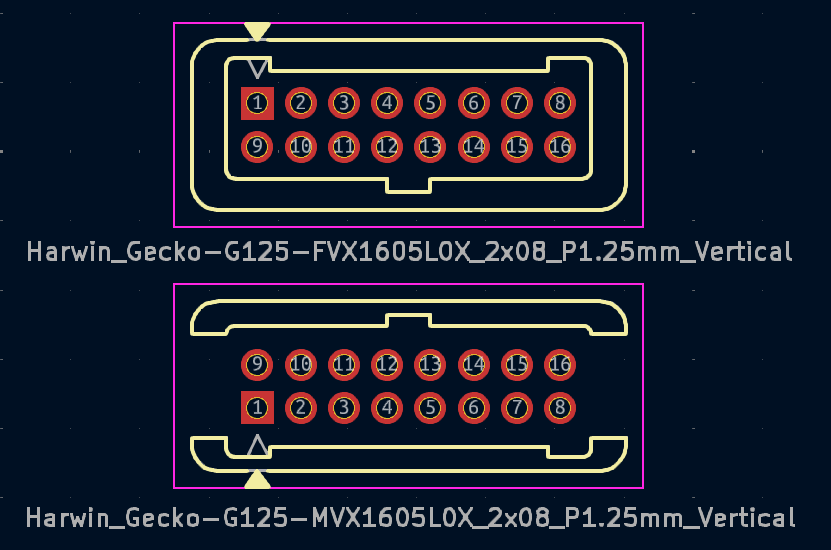

Example:

Notes:

-

The generic connector type [

Standard] defines the shape of the connector-

e.g.

DSUBTabCircular

-

Generic Connector Types

Examples of generic arrayed connectors:

-

PinHeader

-

PinSocket

-

TerminalBlock

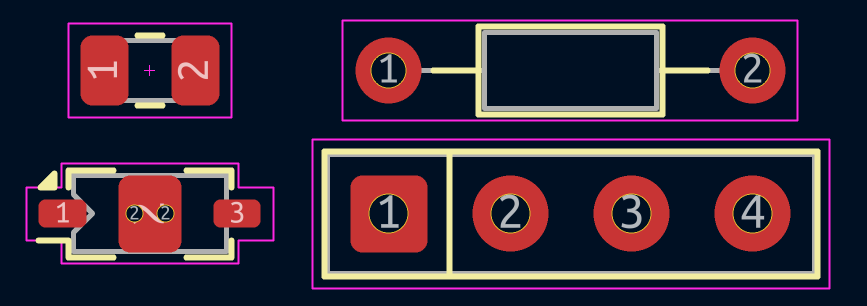

- Connector type - Generic connector style (see notes below)

- MPN - Manufacturer specific identifier (Optional)

- Pin layout - Pin configuration layout (see notes below)

- Pitch - Pin pitch

- Modifiers - Modifiers to connector specifications (pad size, etc) (Optional)

- Orientation - Orientation of connector relative to board

- Options - Extra footprint options (Optional)

Example:

Manufacturer Specific Connectors

Manufacturer series connectors are those which are particular to a particular manufacturer standard.

- MAN - Manufacturer name (Optional)

- Series - Manufacturer series name

- MPN - Manufacturer part number

- Pin layout - Pin layout information (see notes below)

- Pitch - Pad pitch

- Modifiers - Modifiers to connector specifications (pad size, etc)

- Orientation - Direction of connector insertion relative to board plane

- Options - Extra footprint options (Optional)

Example:

Notes:

-

If the footprint is located in a library dedicated to a single manufacturer, then the

MANprefix is not required

F3.7 Fuse naming conventions

The following footprint naming conventions should be used as examples for naming fuse and fuse holder footprints.

If you do not find an appropriate convention that matches a particular footprint type, either contact the KiCad library team or try to match a convention set by existing library components.

In the entries below, variable fields are denoted as follows:

- Fixed fields

- Mandatory fields

- Optional fields

Fuse Holders

- Fuse Type - Type of fuse (Optional)

- MAN - Manufacturer name (Optional)

- Series - Manufacturer series name (Optional)

- MPN - Manufacturer part number (Optional)

- Modifiers - Footprint modifiers if non-standard (Optional)

- Orientation - Orientation of fuse, if multiple orientations are available (Optional)

- Options - Extra footprint options (Optional)

Example:

Examples of Fuse Type field:

-

Automotive fuses:

-

Automotive-Micro2

-

Automotive-Micro3

-

Automotive-LowProfile

-

Automotive-Mini

-

Automotive-ATO

-

Automotive-Maxi

-

Automotive-Bosch

-

Automotive-SFE-[SizeCode]

-

-

Industrial fuses

-

Cylinder-[diameter]x[length]mm

-

Fuses

Cylindrical Fuse

- MAN - Manufacturer name (Optional)

- Series - Manufacturer series name (Optional)

- MPN - Manufacturer part number (Optional)

- Body size - Major fuse dimensions

- Modifiers - Footprint modifiers if non standard (Optional)

- Orientation - Orientation of fuse, if multiple orientations are available (Optional)

- Options - Extra footprint options (Optional)

Example:

Rectangular SMD Fuses

- Imperial size - Imperial case size (Optional)

- Metric size - Metric case size (Optional)

- Modifiers - Footprint modifiers if non standard (Optional)

- Orientation - Orientation with respect to board plane (Optional)

- Options - Footprint options (Optional)

Example:

F4 - General Footprint Requirements

F4.1 Datasheet recommendations take priority

Where conflict exists between datasheet recommendations and KLC requirements, then (in the general case) the datasheet should take priority.

It is important when designing footprints that they adhere to requirements for soldering and assembly - often these requirements have very small tolerance for variation.

If the KLC is at odds with the datasheet, follow the datasheet, and note this difference to the KiCad library team when submitting your contribution.

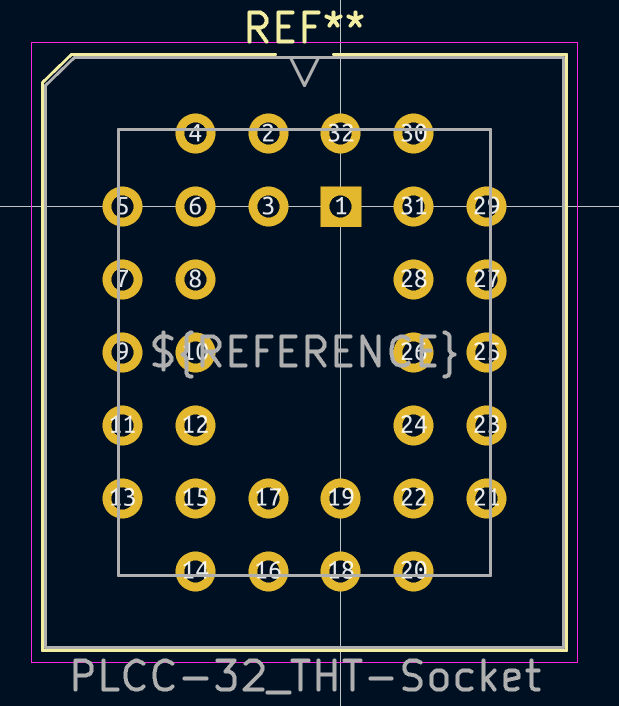

F4.2 Pin 1 should be located at the top left

Footprints should be oriented such that Pin 1 is located in the upper left corner (IPC-7351).

When the pin cannot be the most top-left pin in the footprint, it should be in the top-left quadrant of the footprint.

Exceptions

Two-terminal footprints and other footprints with all pins in a single line should be aligned with pin 1 on the left side.

Multi-purpose connector footprints should be oriented horizontally, with pin 1 on the left side, for easier comparison and alignment with the matching connector.

Footprints for packages with pin 1 located in the middle of one side (e.g. some PLCC and QFN packages) should have pin 1 aligned to the top side.

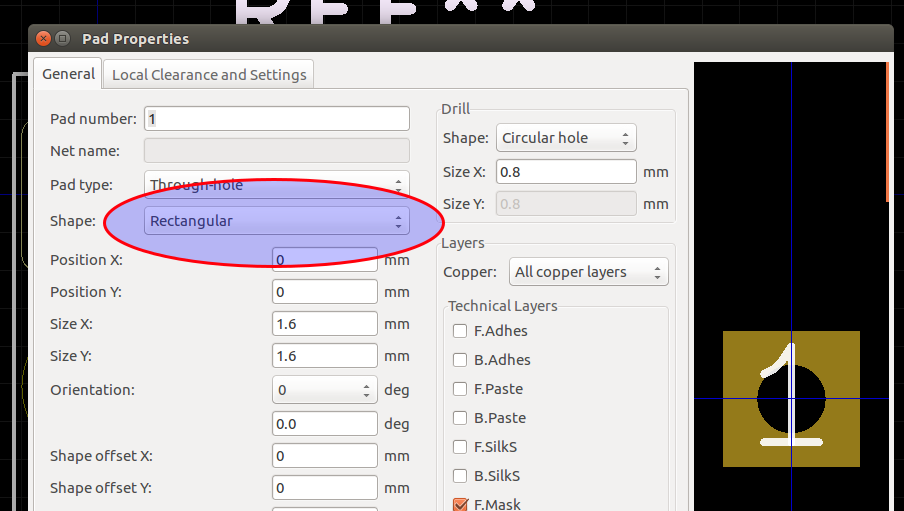

F4.3 Connected copper elements have the same pad number

Footprints that contain multiple pads or conductive elements that are physically connected require special attention:

-

Multiple pads that are physically connected must share the same number

-

Thermal vias (if present) must share the same number as the thermal pad to which they are connected

F4.4 Thermal pads

Manufacturer datasheets may specify that thermal vias should be added to the thermal pad under a device package, to assist in moving heat away from the device.

In such cases the datasheet will usually specify the quantity, size and position of these vias.

In addition to manufacturer requirements, a number of extra conventions should be followed when creating thermal vias.

-

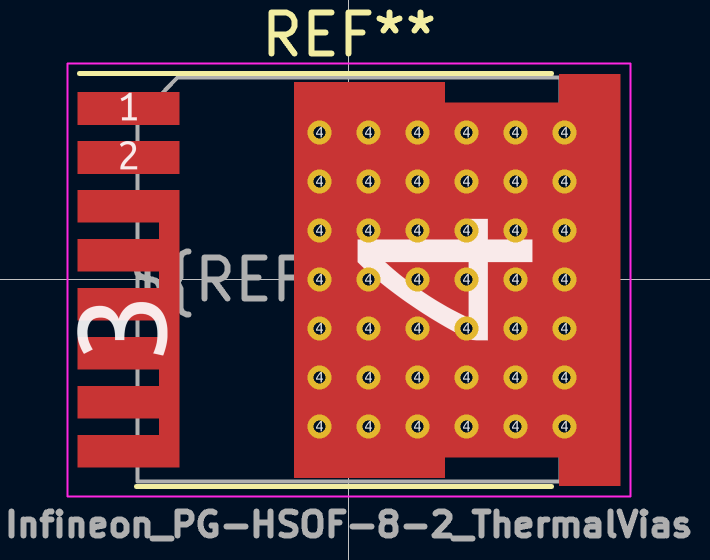

Thermal vias must share the same pad number as the pad on which they are placed

-

Where thermal vias are connected to a pad on the

F.Culayer, a copper pad on theB.Culayer should be added, to provide thermal relief for the via.B.Maskis not to be enabled on theB.Cupad so mask is present. This pad must be large enough to fully surround the via(s) with a margin of>= 0.5mm. Note: If the datasheet gives conflicting advice to the placement of this pad on theB.Culayer, then the datasheet instruction should be given preference.

-

Unless instructed by the datasheet, solder paste must not be placed over thermal via(s) sized 0.3mm or larger. This can cause solder to wick into the via during reflow, and cause solder joint issues.

-

When submitting a footprint with thermal vias, the suffix

_ThermalViasshould be added to the footprint name -

If it does not already exist, a second version of the footprint without the thermal vias should be added. Note: This second version should not have the

_ThermalViassuffix in the footprint name. -

The hole size should be 0.2mm - 0.3mm, unless the datasheet specifies otherwise. Note: While 0.3mm is manufacturable using lowest cost processes, 0.2 is better for reflow and no longer that expensive to manufacture, so 0.2mm is preferred for smaller parts.__

F4.5 Specifying footprint keepout areas

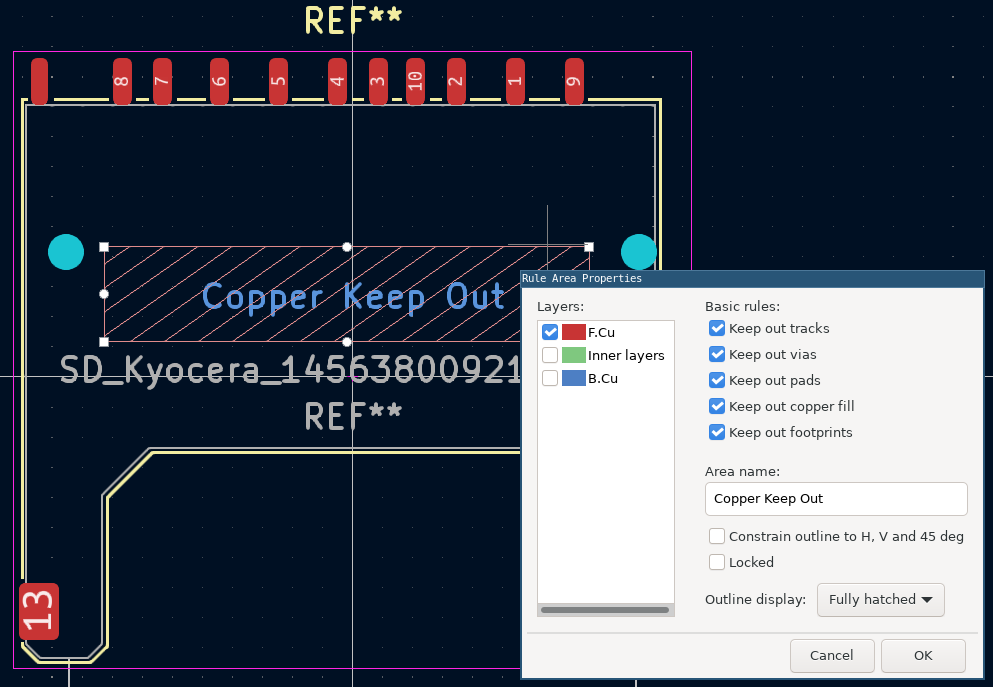

Footprint keepout area must be drawn using as a 'rule-area (keepout)' when necessary or recommended in manufacturer’s datasheet.

The area should be named according to its use (e.g. 'Antenna Keepout'), this name must be used to name the area as text also on the User.Comments layer.

-

Select only the appropriate layers

-

Check all basic rules (

Constrain outlineandLockedmust be kept unchecked) -

Outline display must be

Fully hatched

Example:

Example of an area, named both in the dialog and on the User.Comments layer:

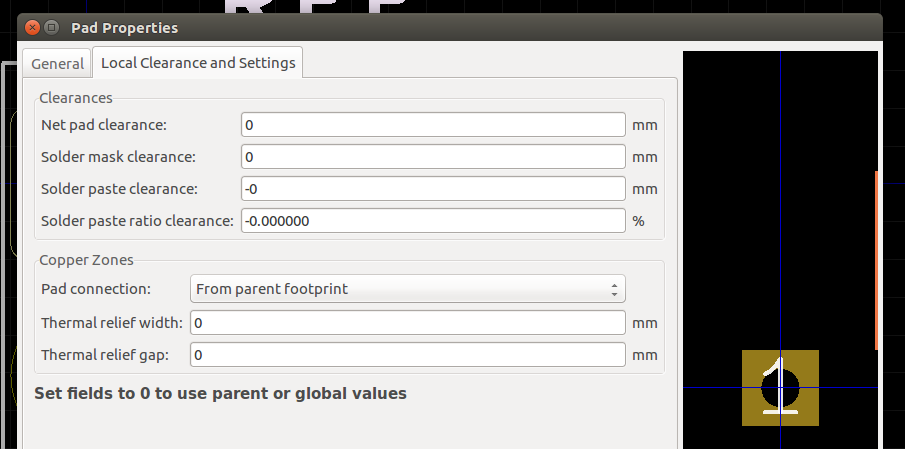

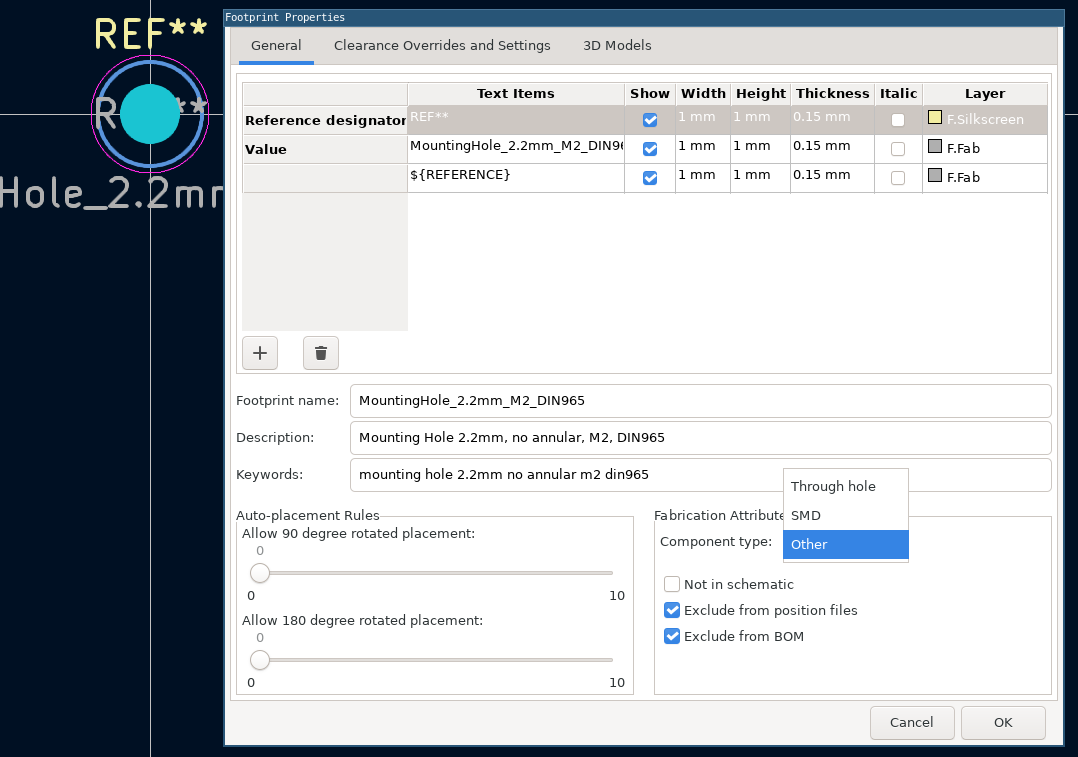

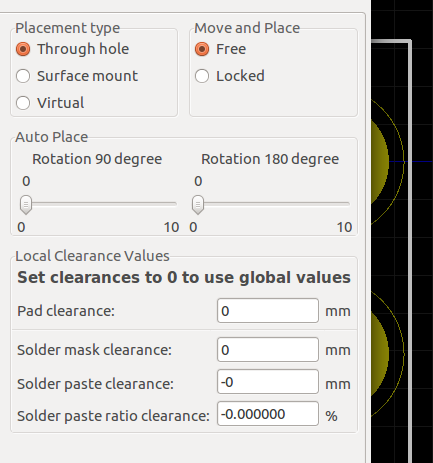

F4.6 Local clearance and settings should be set to zero

Pad clearance values are determined using a priority system, which checks the following locations for clearance values, in descending order of priority. If a particular setting reads as zero (0) then it is ignored, and the next location is checked.

-

Local pad settings - If an individual pad specifies clearance values, these are used

-

Footprint settings - If clearance values are specified in the Footprint Properties window, these are used

-

Global settings - If no values are specified as above, then the global values (as specified in PCB settings dialog) are used.

Unless there is a specific reason for setting explicit values for local clearance values for pads or pins, they should be left at zero (0).

Exceptions:

If the component datasheet calls for specific clearance values for a particular pad (or the entire footprint) then these values should be used as appropriate.

F5 - Layer Requirements

F5.1 Silkscreen layer requirements

The silkscreen is printed to the external surface of a PCB to aid in component identification and orientation. Typically this layer contains the component RefDes to locate components on the board after assembly.

KiCad refers to the silkscreen layers as:

-

F.SilkS- Front silkscreen layer -

B.SilkS- Back silkscreen layer

The following elements must be provided on the silkscreen.

-

Reference Designator must be drawn on

F.SilkSlayer-

Text size =

1.00mm -

Text thickness =

0.15mm

-

-

Silkscreen line width is between {

0.10mmand0.15mm}:-

Silkscreen line width should nominally be

0.12mm -

0.1mmis allowed for high density designs -

0.15mmis allowed for low density designs

-

-

Silkscreen must not be placed over pads or areas of exposed copper

-

Clearance between silkscreen and exposed copper elements is recommended to be 0.2mm.

-

Clearance must be at least the silkscreen line width or pad mask expansion, whichever is greater.

-

-

For SMD footprints, silkscreen must be fully visible after boards assembly (no silkscreen allowed under component)

-

For THT components, additional silkscreen may be placed under component to aid in assembly process

-

Polarity marking / Pin-1 designator must be drawn on the

F.SilkSlayer -

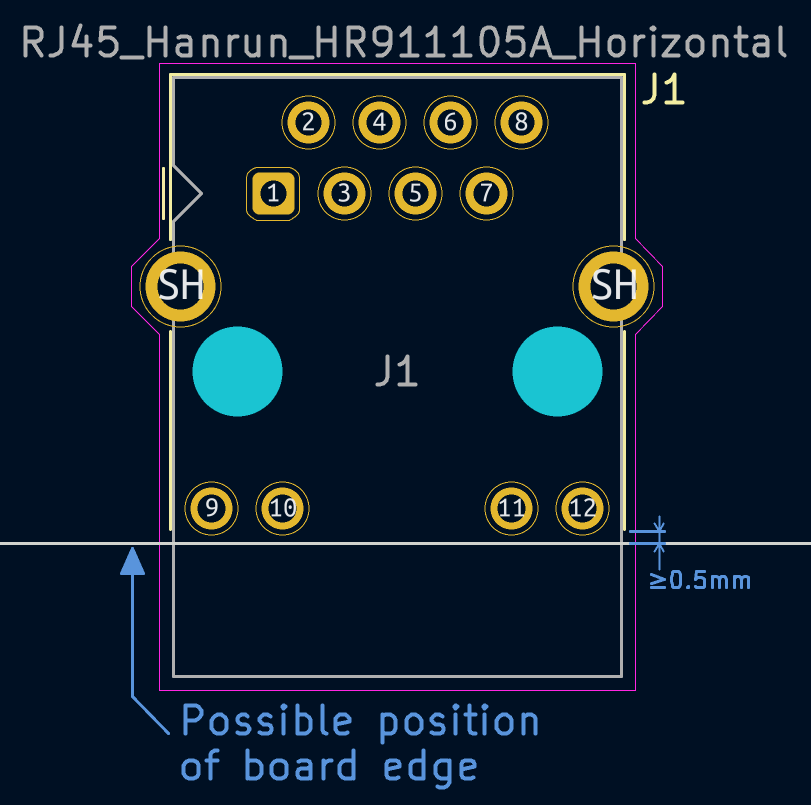

When components are expected to protrude past the board edge (e.g. connectors), silkscreen should not be placed such that a reasonably-placed component has silkscreen outside the board

-

Clearance between silkscreen and board edges should be at least 0.5mm

-

Polarity marking / Pin-1 designator

-

The prefered style for SMD packages is a filled chevron

▶-

It should positioned inside the courtyard to prevent silkscreen overlap

-

It can be rotated by 45° for a better fit

-

-

Examples other established and acceptable styles

-

for SMD devices

-

⊔shape for SMD diodes -

For small packages (0201 diodes, …) a 0.25mm dot should be used.

-

-

for THT and SMD packages

-

corner bracketorextra linefor connectors -

+sign for SMD capacitors

-

-

Follow established styles that already exist in the target library

-

-

If the device has a marking that is not on Pin-1 (popular on digital LEDs), the marking needs special attention

-

The digit

1is put on the silkscreen marker next to the pin numbered 1 -

The silkscreen polarity marking is placed according to the physical marking on the device

-

-

The marking must be visible after board assembly for inspection and debug purposes

-

It also should be visible after connector mating

-

Examples

Examples of silk for non-polarized components

Examples of silkscreen for polarized components

Example of a connector with silkscreen that is "pulled back" from possible board edges:

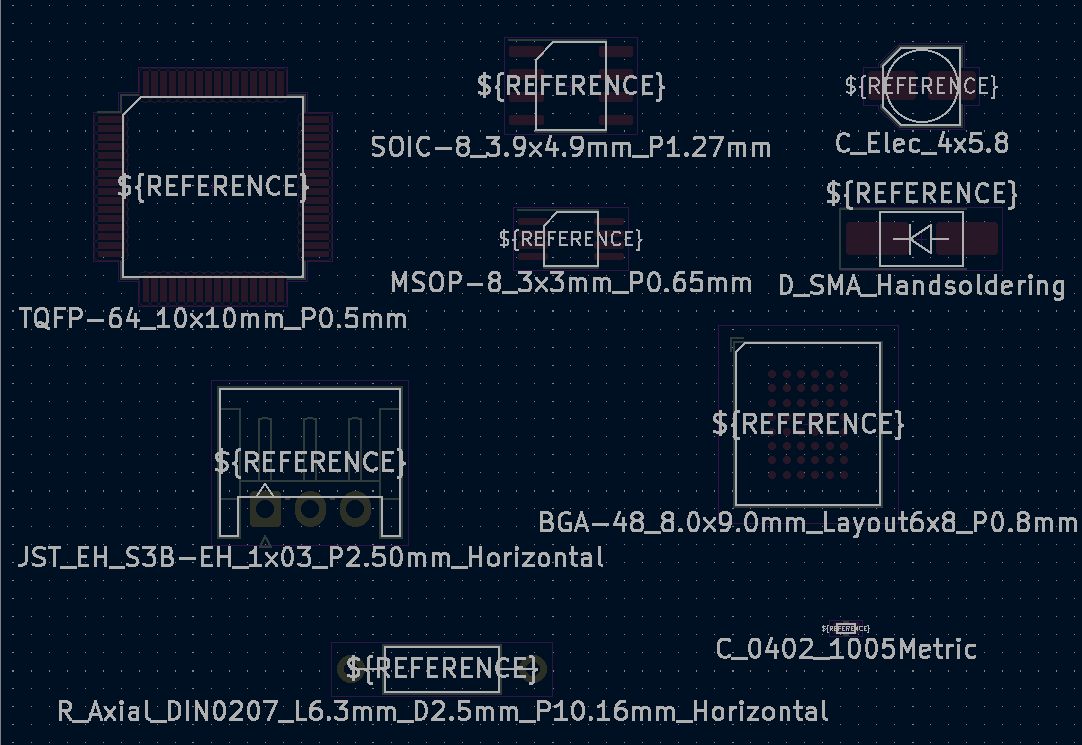

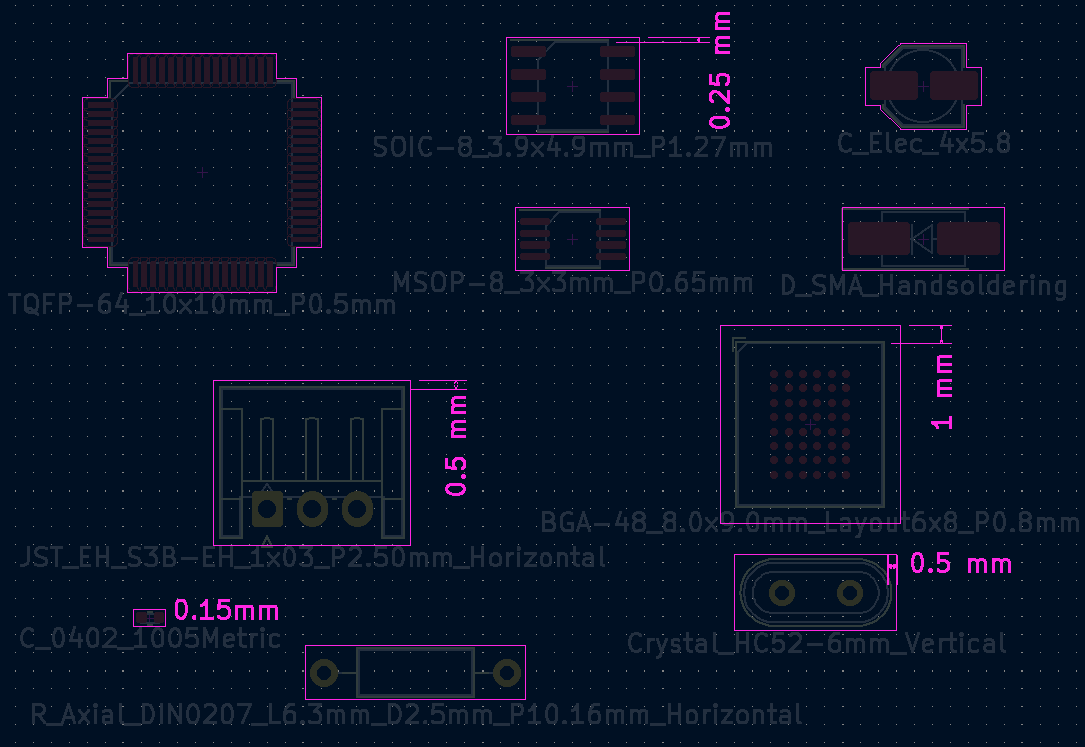

F5.2 Fabrication layer requirements

The fabrication layers are used to display the simplified mechanical outline of components on the PCB.

KiCad refers to the fabrication layers as:

-

F.Fab- Front fabrication layer -

B.Fab- Back fabrication layer

The following elements must be provided on the fabrication layer(s)

-

Simplified component outline must be provided on

F.Fablayer-

Outline uses line width between {

0.10mmand0.15mm} (recommended0.10mm) -

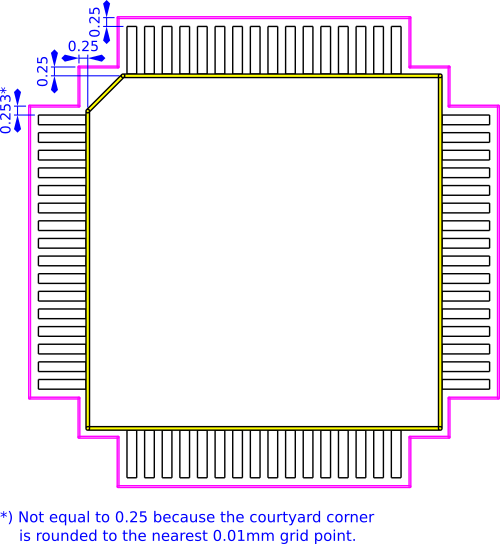

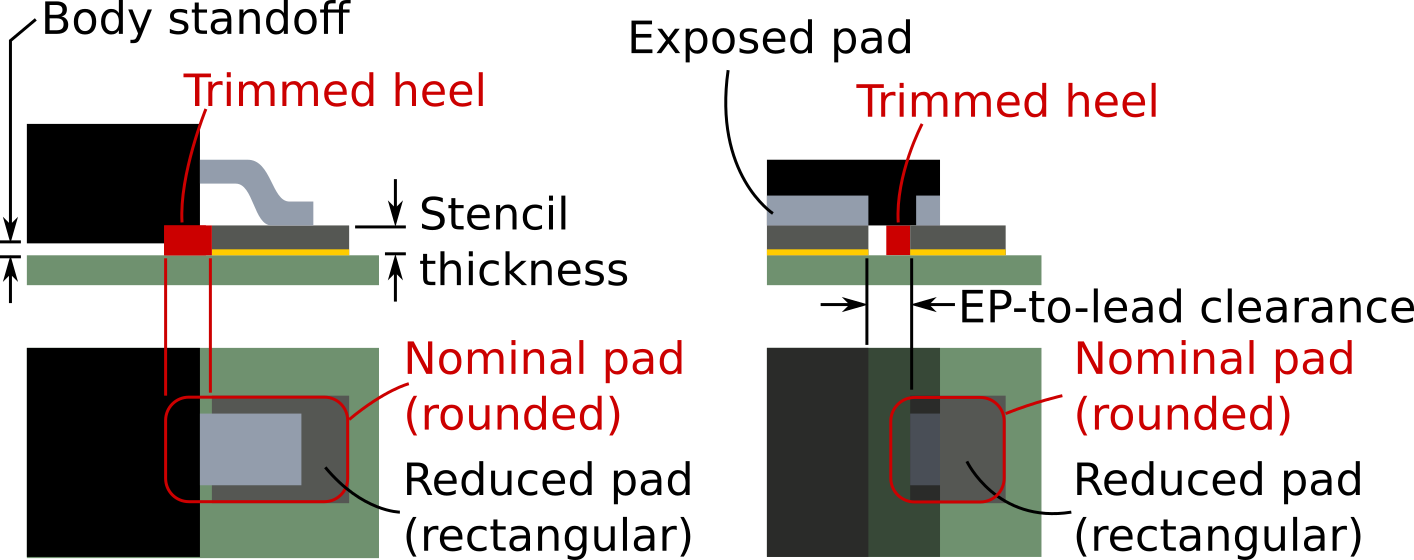

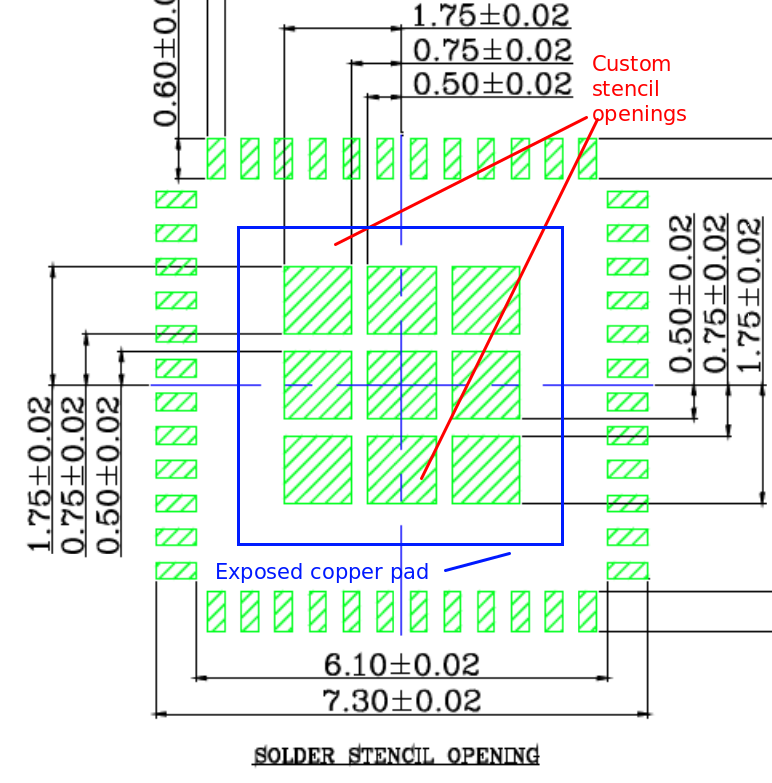

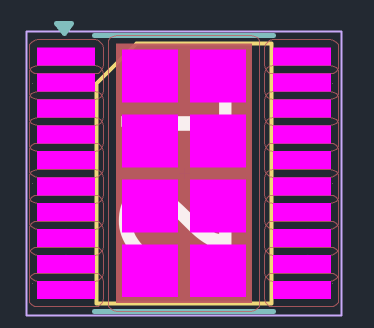

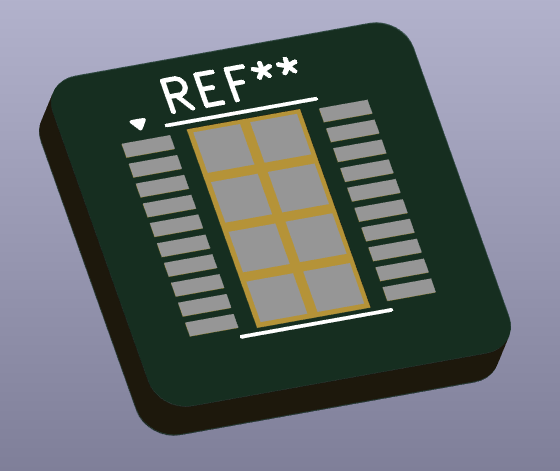

Outline should be simplified and not display complex features