F5.1 Silkscreen layer requirements

The silkscreen is printed to the external surface of a PCB to aid in component identification and orientation. Typically this layer contains the component RefDes to locate components on the board after assembly.

KiCad refers to the silkscreen layers as:

-

F.SilkS- Front silkscreen layer -

B.SilkS- Back silkscreen layer

The following elements must be provided on the silkscreen.

-

Reference Designator must be drawn on

F.SilkSlayer-

Text size =

1.00mm -

Text thickness =

0.15mm

-

-

Silkscreen line width is between {

0.10mmand0.15mm}:-

Silkscreen line width should nominally be

0.12mm -

0.1mmis allowed for high density designs -

0.15mmis allowed for low density designs

-

-

Silkscreen must not be placed over pads or areas of exposed copper

-

Clearance between silkscreen and exposed copper elements is recommended to be 0.2mm.

-

Clearance must be at least the silkscreen line width or pad mask expansion, whichever is greater.

-

-

For SMD footprints, silkscreen must be fully visible after boards assembly (no silkscreen allowed under component)

-

For THT components, additional silkscreen may be placed under component to aid in assembly process

-

Polarity marking / Pin-1 designator must be drawn on the

F.SilkSlayer -

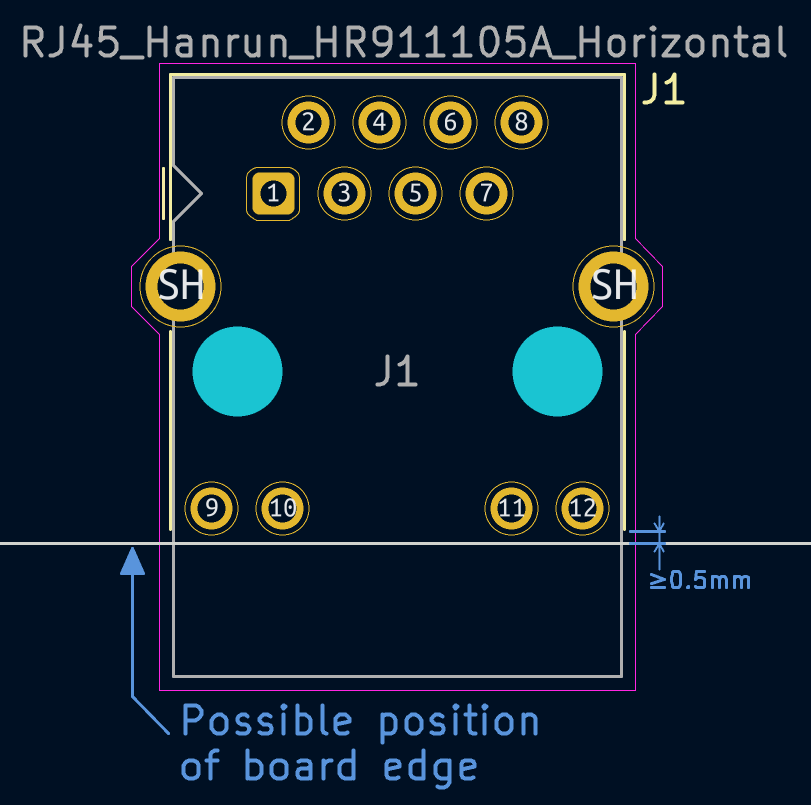

When components are expected to protrude past the board edge (e.g. connectors), silkscreen should not be placed such that a reasonably-placed component has silkscreen outside the board

-

Clearance between silkscreen and board edges should be at least 0.5mm

-

Polarity marking / Pin-1 designator

-

The prefered style for SMD packages is a filled chevron

▶-

It should positioned inside the courtyard to prevent silkscreen overlap

-

It can be rotated by 45° for a better fit

-

-

Examples other established and acceptable styles

-

for SMD devices

-

⊔shape for SMD diodes -

For small packages (0201 diodes, …) a 0.25mm dot should be used.

-

-

for THT and SMD packages

-

corner bracketorextra linefor connectors -

+sign for SMD capacitors

-

-

Follow established styles that already exist in the target library

-

-

If the device has a marking that is not on Pin-1 (popular on digital LEDs), the marking needs special attention

-

The digit

1is put on the silkscreen marker next to the pin numbered 1 -

The silkscreen polarity marking is placed according to the physical marking on the device

-

-

The marking must be visible after board assembly for inspection and debug purposes

-

It also should be visible after connector mating

-

Examples

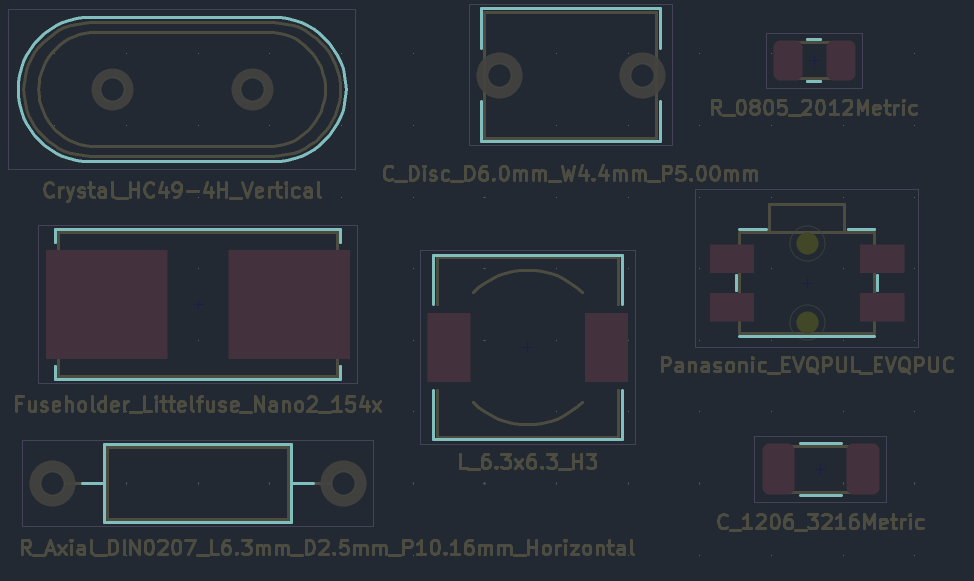

Examples of silk for non-polarized components

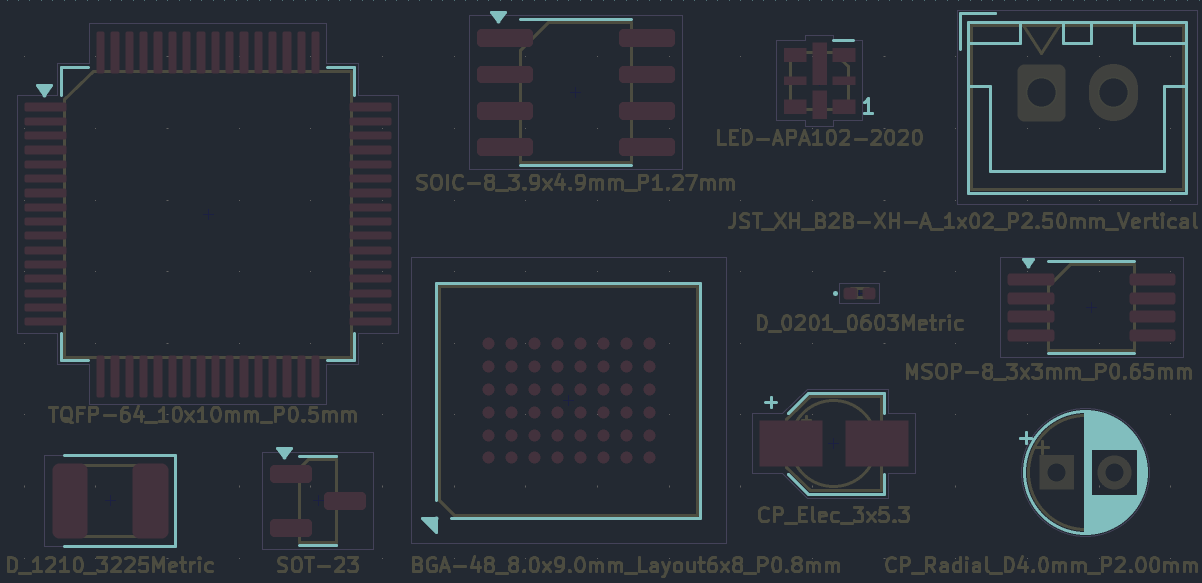

Examples of silkscreen for polarized components

Example of a connector with silkscreen that is "pulled back" from possible board edges: